What is the UmiPack Moisture Meter for Wood Packages?

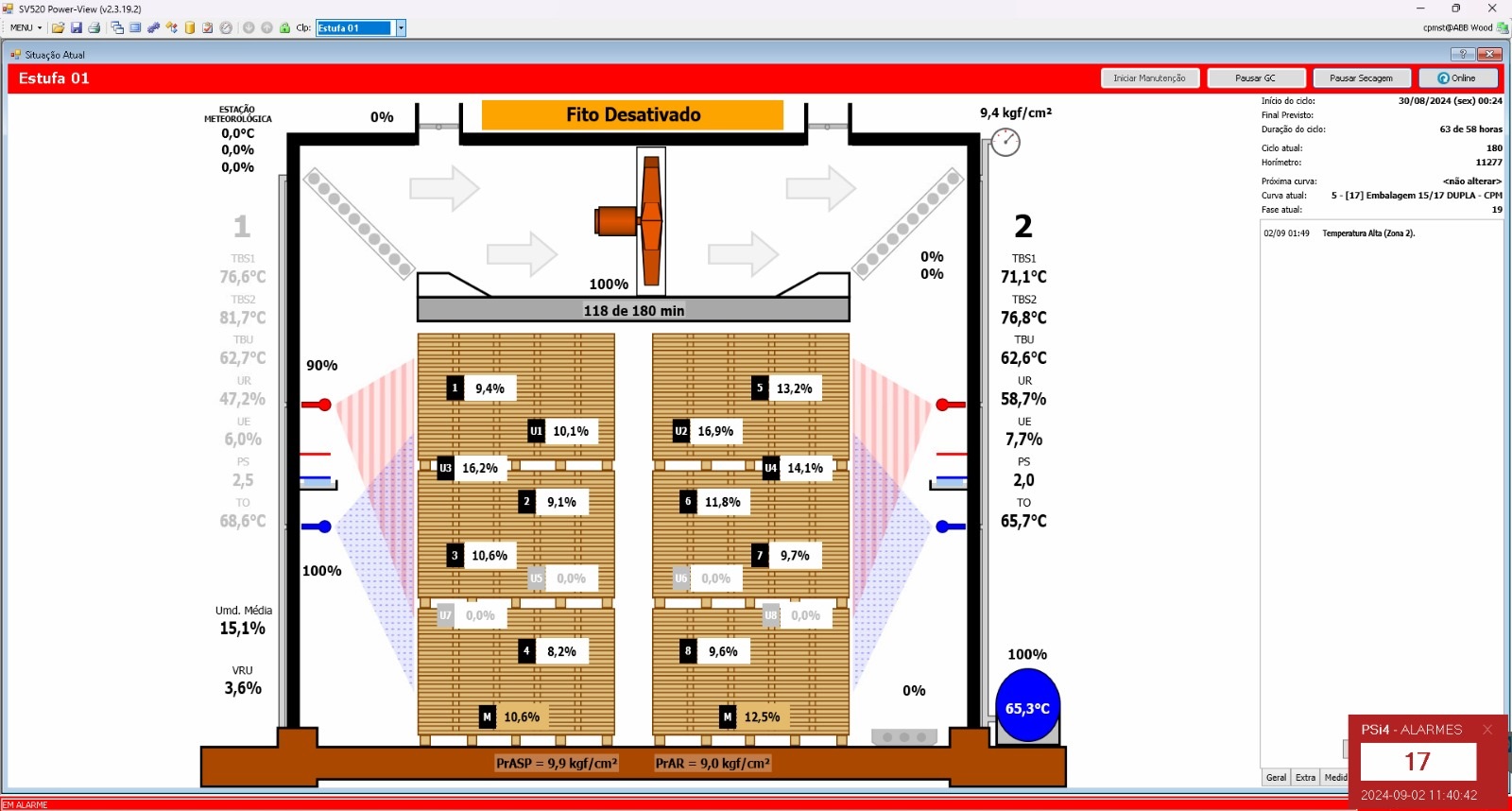

The UmiPack is an advanced wood moisture measurement system designed to operate within drying kilns. It represents a significant innovation in moisture control, replacing traditional resistive pin sensors with a system that uses capacitive technology, capable of accurately and non-invasively measuring the moisture content of entire stacks of wood. This system not only monitors the surface of the boards but also penetrates the interior of the package, providing a comprehensive and representative reading of the drying conditions across different layers.

Why Has UmiPack Revolutionized Moisture Measurement Methods?

UmiPack has revolutionized the industry by completely eliminating the need for pin sensors. Traditionally, these pins were driven into the wood, which not only caused damage to the material but also limited the measurement to a single specific point. This method was flawed as it failed to provide a clear view of moisture behavior throughout the entire wood package.

With UmiPack, this limitation has been overcome. Its dielectric measurement system using metal plates provides a continuous and accurate reading of almost the entire wood stack, generating a representative average of the moisture content. This advancement reduces drying errors, optimizes the energy consumption of kilns, and improves the final quality of the wood. Additionally, it eliminates the need for frequent replacement of damaged or poorly positioned pins, reducing operational costs.

How Does UmiPack Achieve Such Precise Measurements?

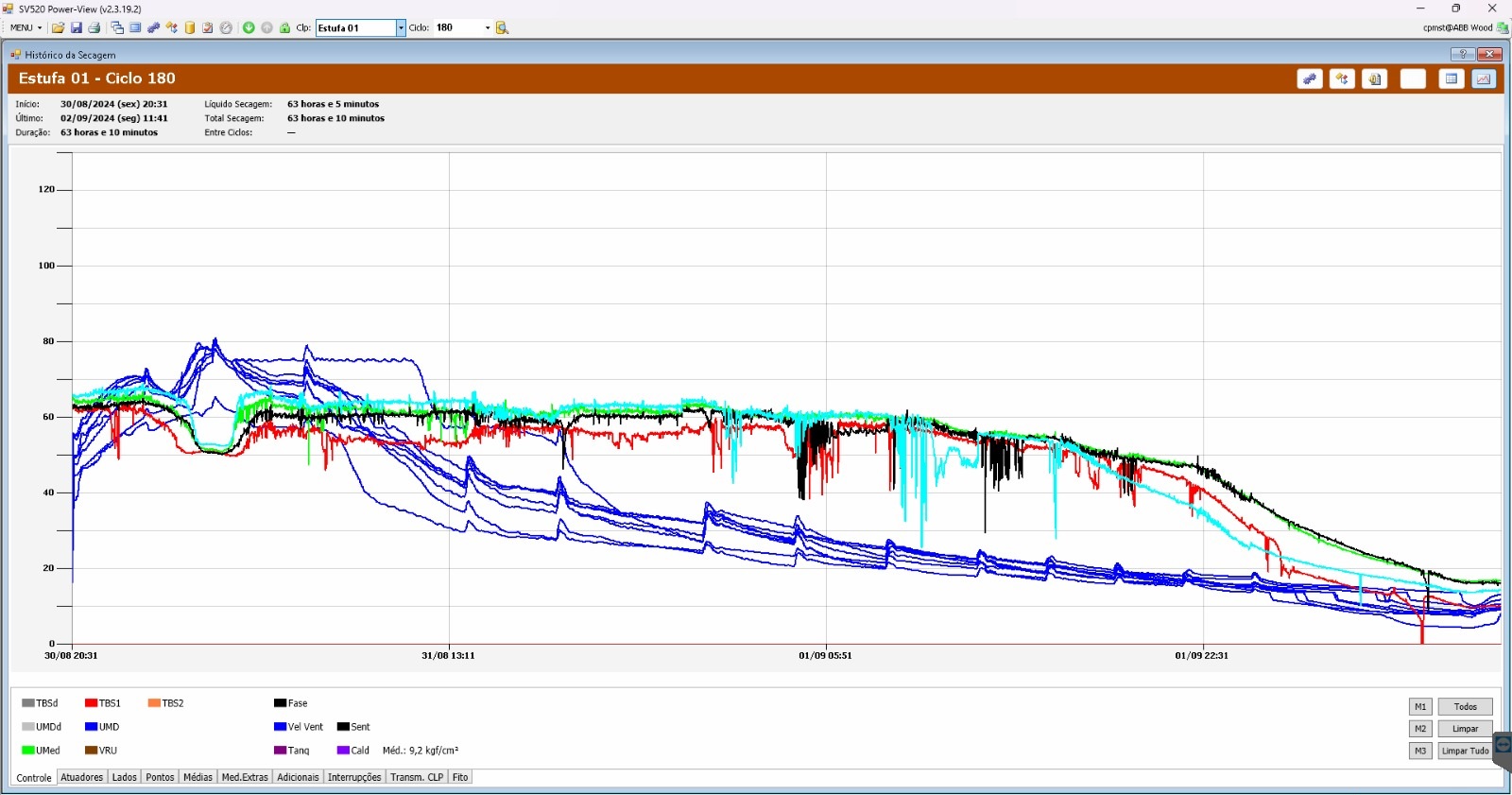

The precision of UmiPack stems from its use of capacitive technology, which is based on detecting dielectric variations caused by the presence of water in the wood. This method monitors the movement of water molecules indirectly, without the need to insert sensors into the material. The result is an accurate measurement of moisture in different parts of the package, allowing for refined control of the drying process.

In addition to being more efficient, the system ensures the structural integrity of the wood, as it does not damage it, and allows for real-time data collection. This provides operators with greater confidence in the process, increasing predictability and reducing the risk of material loss due to improper drying.

Benefits of UmiPack for the Wood Drying Industry

- Enhanced Accuracy: Measurement at multiple points within the package, and measuring more boards within the same wood package, allows for greater process control, resulting in more uniform drying and higher quality products.

- Cost Reduction: By eliminating the need for disposable pin sensors, the costs associated with purchasing and maintaining these components are eliminated, as well as minimizing damage to the wood.

- Ease of Operation: Simple installation and operation without the need for drilling make UmiPack an efficient and easy-to-handle solution for operational teams.

- Sustainability: More precise moisture control reduces kiln energy consumption, optimizing resource use and lowering the environmental impact of the operation.

UmiPack is a cutting-edge solution designed to meet the needs of the modern wood industry, focusing on efficiency, accuracy, and large-scale sustainability.

Applications

Any industry that dries wood can use the UmiPack system to replace pin sensors. Below are some practical application examples:

1. Production of Structural Woods

In the manufacture of structural components such as laminated beams and columns, uniform drying is essential to ensure the strength and stability of the final product. UmiPack monitors the moisture content of the entire wood package, ensuring that each piece meets the technical specifications required in the construction sector.

2. Drying of Boards for Furniture

Furniture industries use UmiPack to ensure that boards are dried evenly, avoiding issues such as warping and cracking. Precise moisture measurement is crucial to ensuring the durability and appearance of furniture.

3. Manufacture of Wooden Pallets

In the production of pallets, proper wood drying is crucial to prevent problems such as insect infestation, fungus growth, and decay during use. UmiPack is used to ensure that the wood is dried evenly, reaching the moisture levels required by international standards. This not only improves the durability of the pallets but also meets export and safe storage requirements.

And why use the Marrari equipment?

Because our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0. Thus creating a more efficient, productive and modern production environment!

If you want to know more about us and our gauges, visit our Facebook or LinkedIn.

Want to know more technical information about the equipment? Check below for more information! and ask for your quote!