WHAT IS PRO X PRODUCTION CONTROLLER?

Pro X production controler is a comprehensive solution for any process that requires precision in counting, material sizing, and longitudinal or transverse machine and line control. It also takes the first step towards Industry 4.0, incorporating OEE methods for production. The equipment controls, second by second, all data of the pieces entering or leaving the line, measuring produced quantities, dimensions, and quality, allowing complete production and machine management on the production line.

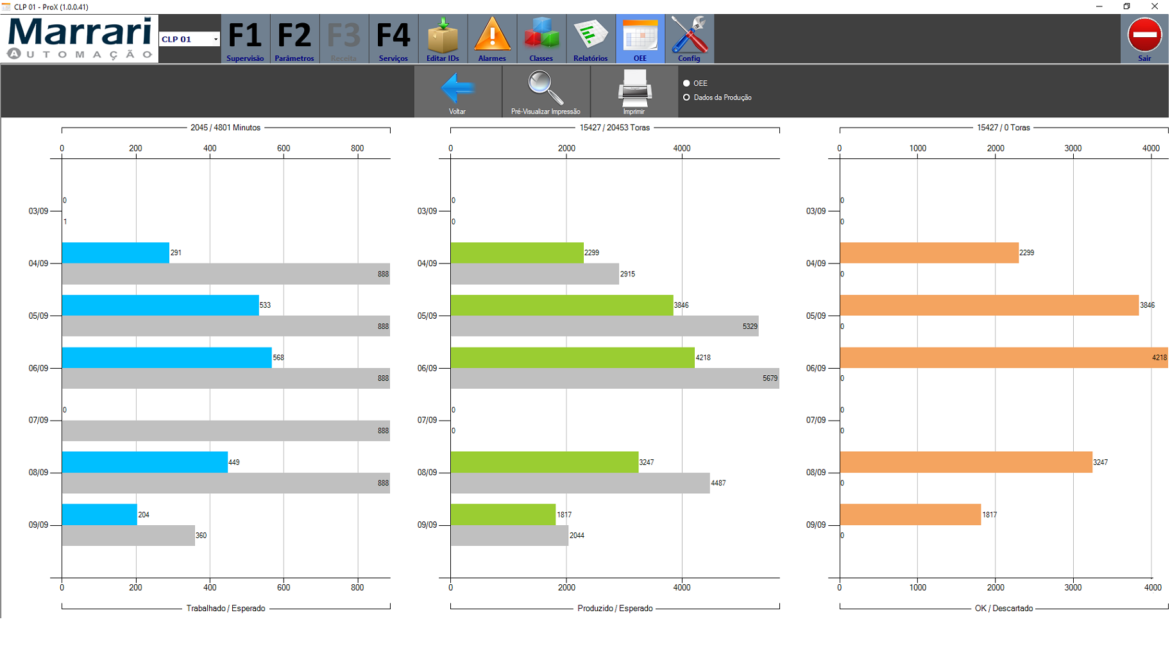

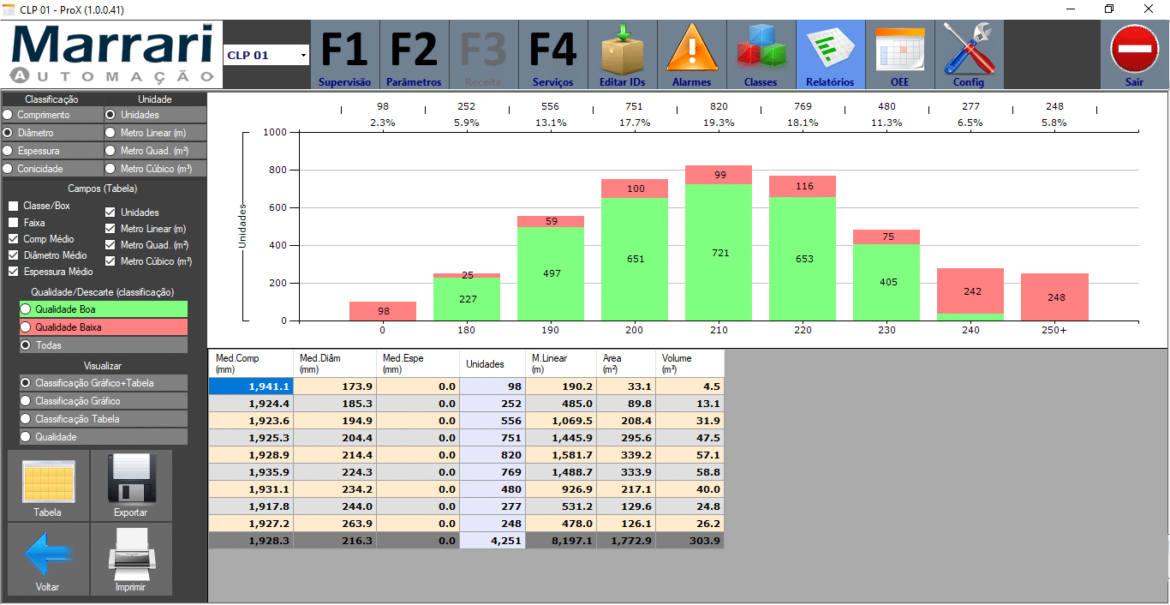

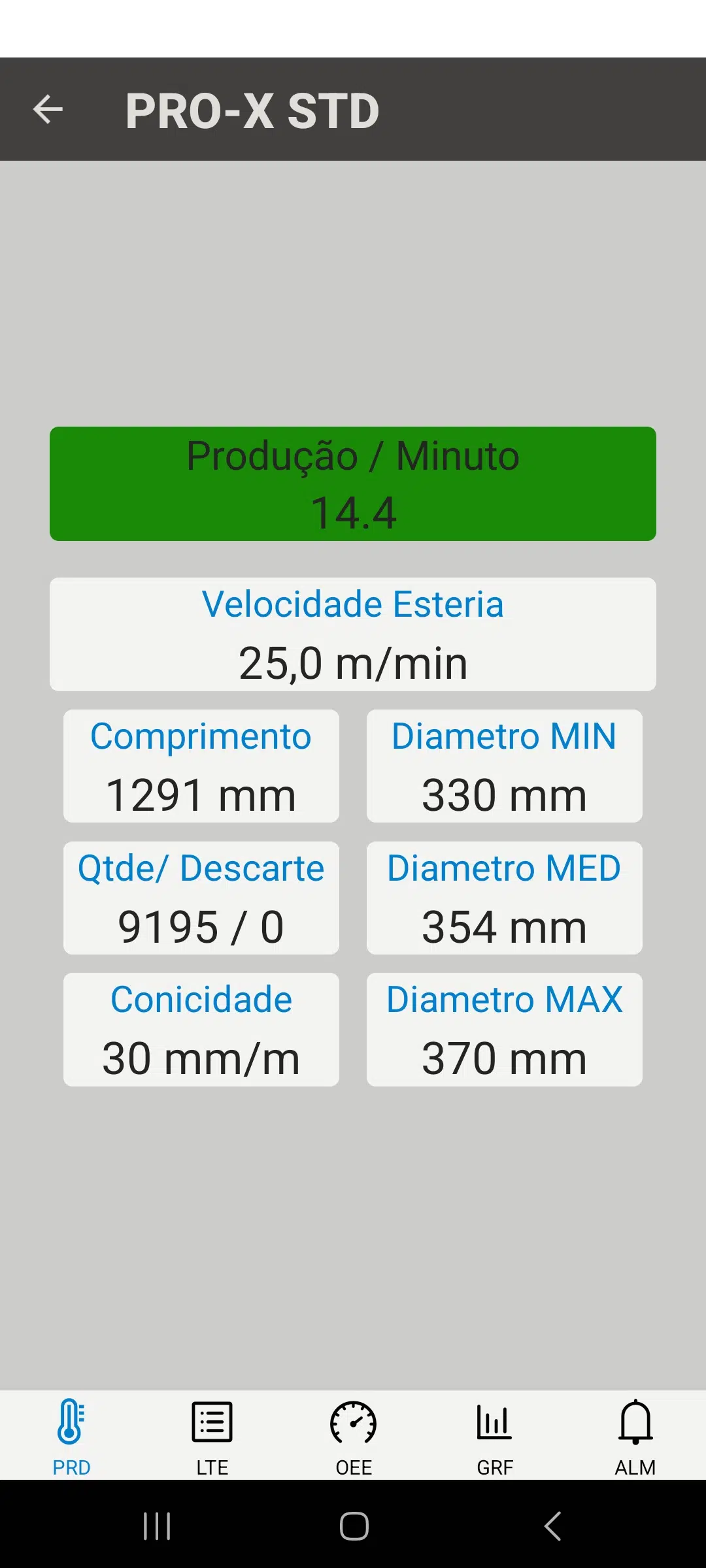

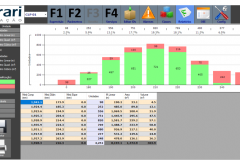

All this data is then presented in a straightforward dashboard on your computer or mobile for visual control of your line at any time, with the ability to generate reports of data and events that occurred on the line (see photos above).

WHY USE PRO X IN YOUR PROCESS?

A production controller like Pro X will provide you with complete data about your production, such as quantities of pieces produced, their dimensions, daily, monthly, and annual production goals. This allows you to have a 360º view of your process, providing data to help your factory floor team maintain production standards to always achieve the goals set by your manager inserted in the Pro X software.

Learn about the importance of controlling production and efficiency in your process by clicking here.

WHAT OTHER FEATURES DOES IT OFFER FOR MANAGEMENT?

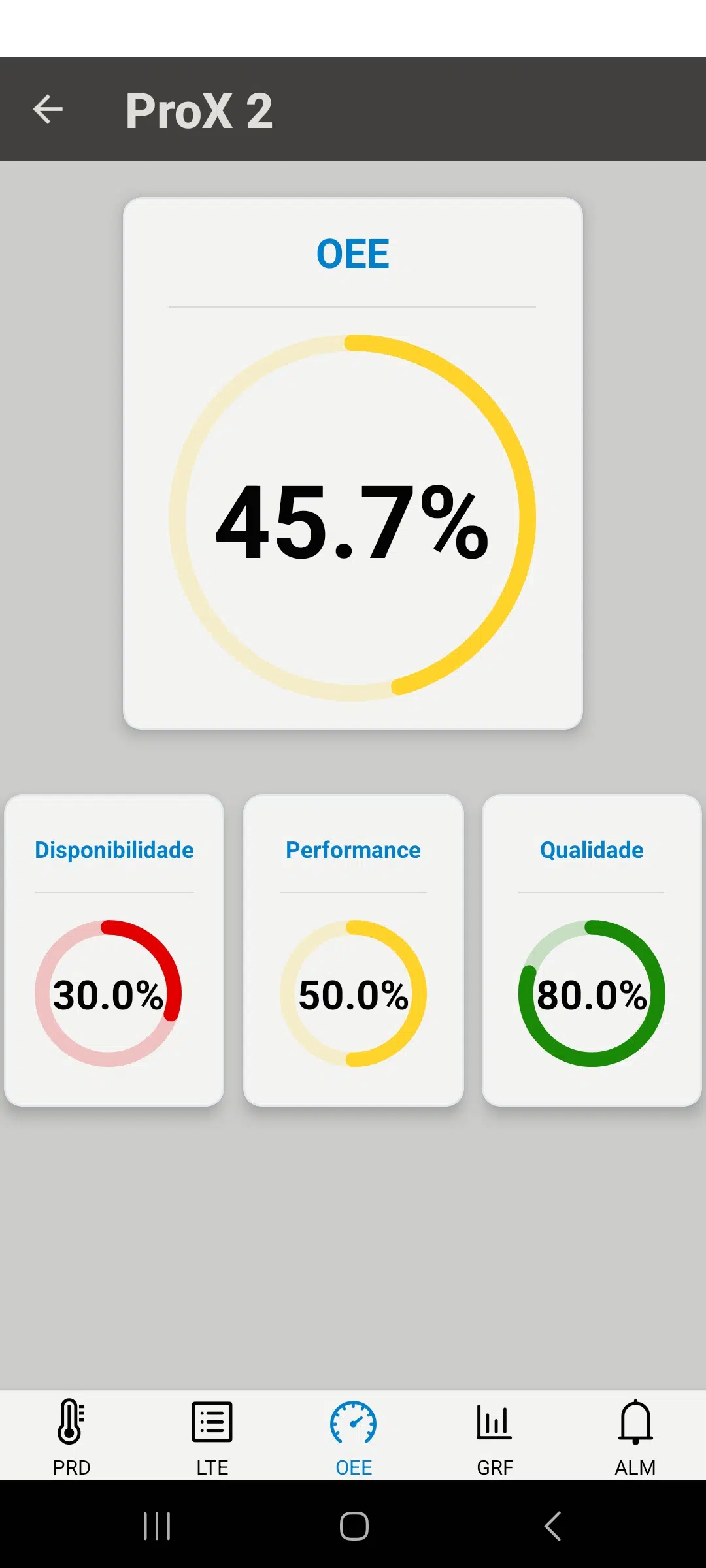

It also tracks various performance indicators, such as OEE (Overall Equipment Effectiveness), which generates reports and graphs on the performance of your line or machine for which Pro X is configured. OEE refers to three essential indicators for your process: the quality of the material produced, i.e., whether good-quality pieces are being produced and not being rejected at the end of the process and turning into scrap, machine availability time, showing how much time in the total measured period your line was producing, and if it stopped, why it stopped with reasons to be resolved. Finally, production performance uses the two previous data and provides a percentage of the total efficiency of your process.

Learn more about OEE and its importance in the current scenario of world production by clicking here.

Benefits of using a production controller:

The Pro X production control offers a range of significant benefits to optimize and efficiently manage your production processes. Here are some of the key advantages:

- Real-time Precision and Control: Pro X allows second-by-second control of all piece data, including produced quantities, dimensions, and quality. This provides a real-time view of the production line’s performance.

- Comprehensive Production Management: By providing comprehensive data on production, including quantities of pieces produced and daily, monthly, and annual goals, Pro X enables comprehensive production management. This facilitates the maintenance of production standards and the achievement of established goals.

- Intuitive Dashboard: The collected data is presented in a straightforward dashboard, accessible through computers or mobile devices. This offers convenient visual control of the production line at any time.

- Detailed Reports: The ability to generate reports on data and events in the production line provides valuable information for analysis and informed decision-making.

- Integration with Industry 4.0: Pro X represents a step towards Industry 4.0, incorporating Overall Equipment Effectiveness (OEE) methods to enhance efficiency and automation in production processes.

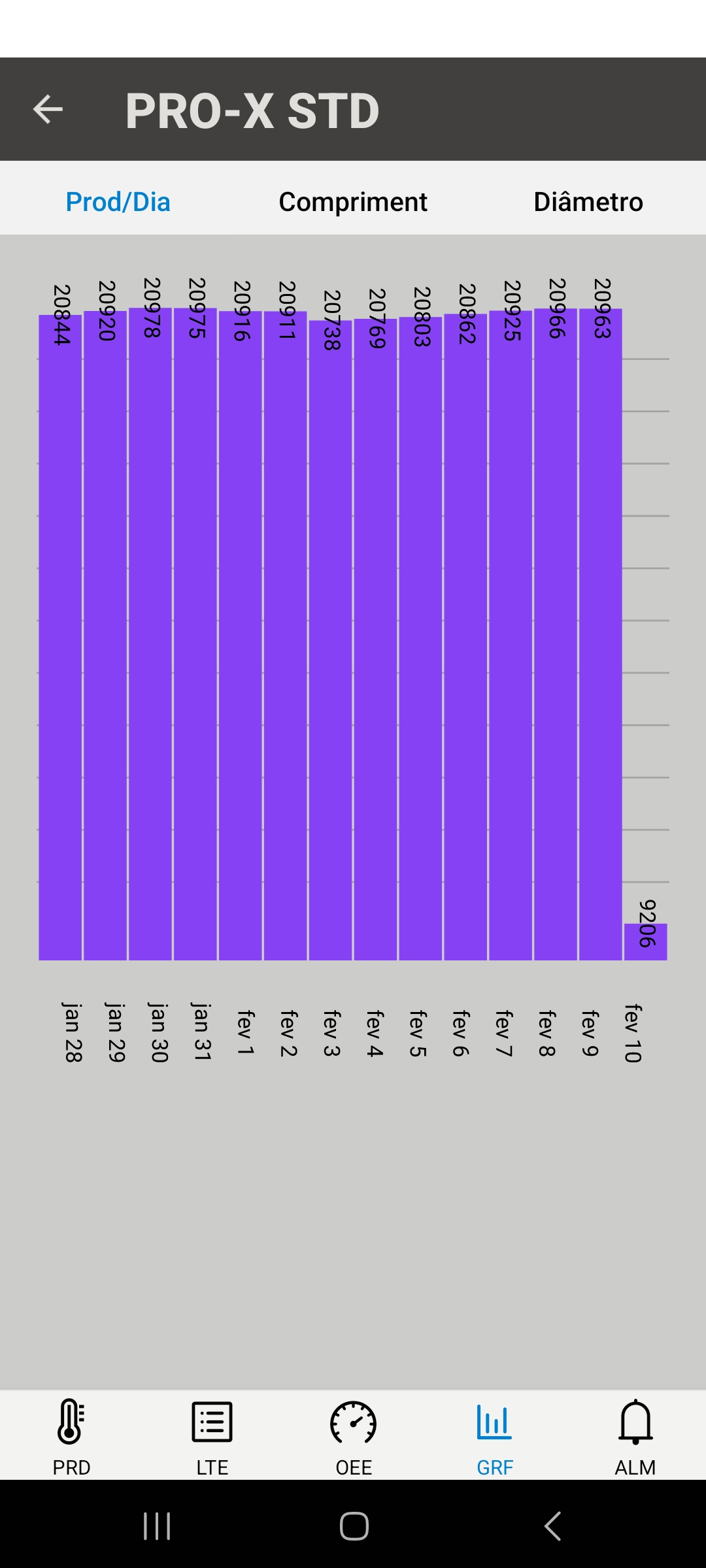

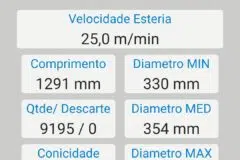

- Remote Monitoring via Application: The development of a real-time monitoring application provides the convenience of staying connected to production operations. This includes essential data such as production quantity, compliance with daily/weekly goals, machine stops, current OEE index, and more.

- Performance Indicator Tracking: Pro X tracks crucial performance indicators such as OEE, providing a comprehensive understanding of material quality produced, machine availability time, and overall production performance.

APPLICATION FOR PRODUCTION CONTROL

As we know the importance of always being connected to everything that happens in your production, Marrari has also developed an application for real-time monitoring of your line, showing essential data such as the quantity produced, whether it is within or outside the daily/weekly target, machine stops with their reasons and operators, the current OEE index, monitoring of each piece that passes through Pro X, and much more.

AND WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss, using methods such as OEE and Industry 4.0. Thus, creating a more effective, productive, and modern production environment!

If you want to know more about us and news from the automation world, visit our blog, Facebook, or LinkedIn.

GUARANTEE

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!