What is the new easy wood drying controller?

The New Easy wood drying Controller, is the perfect solution for small drying plants where the factor economy in the facility and in the steam and energy is determinant.

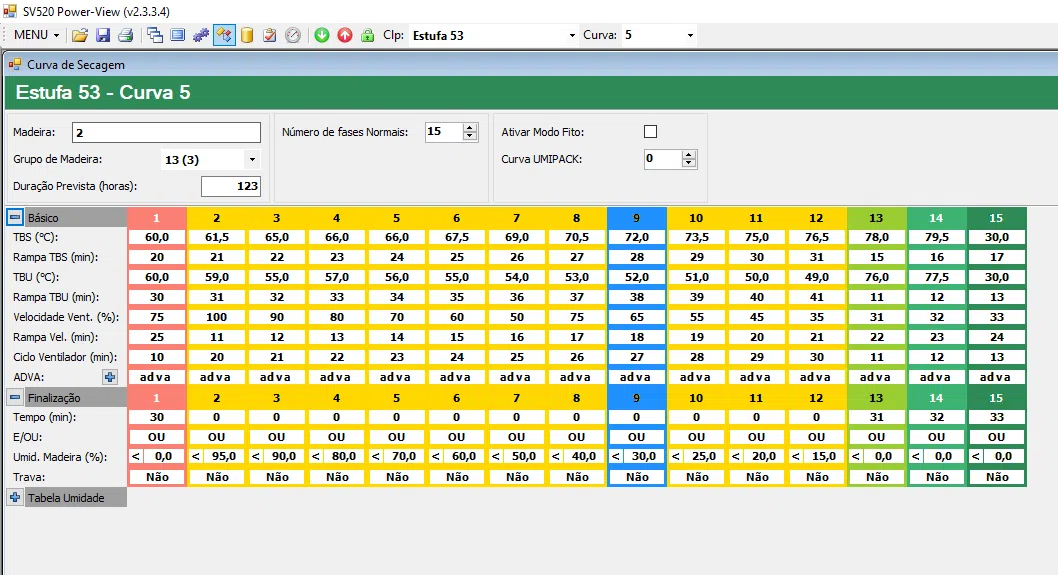

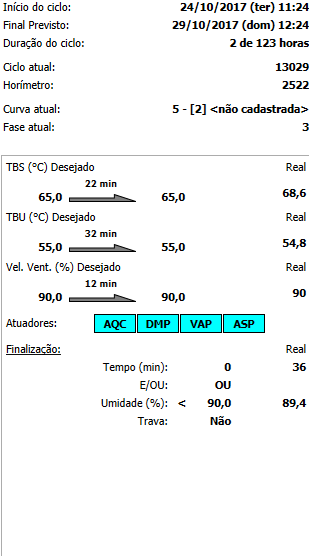

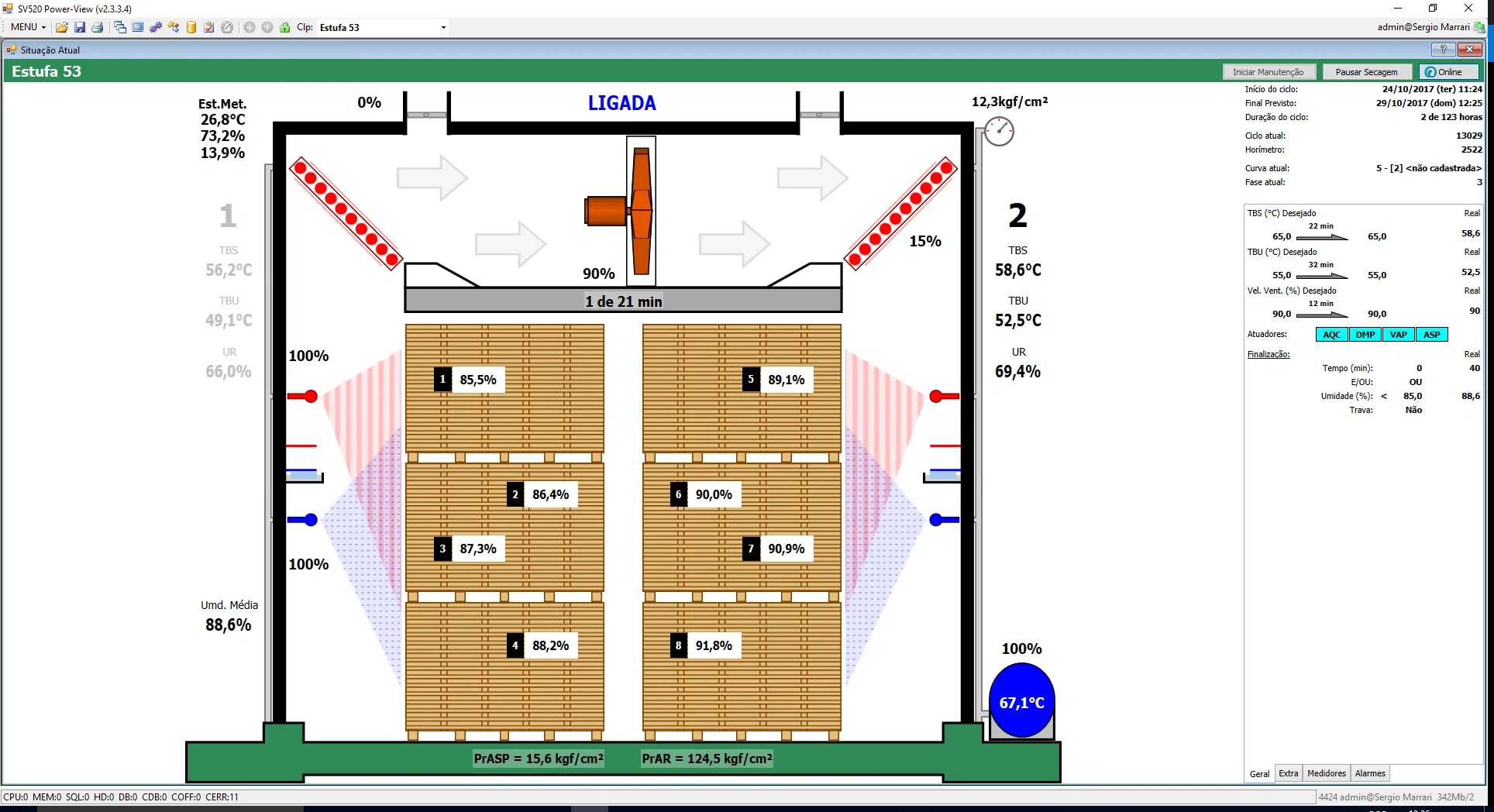

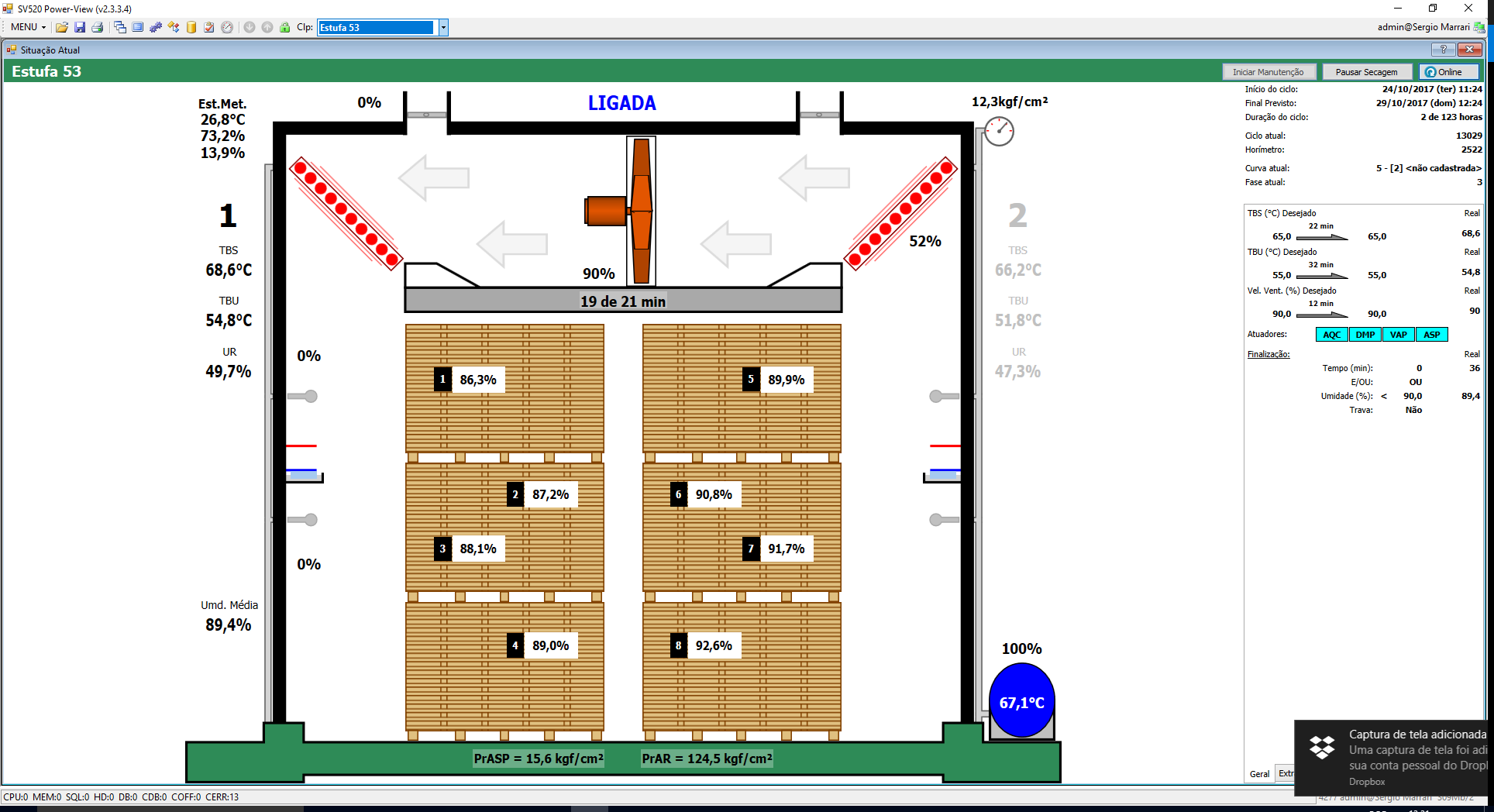

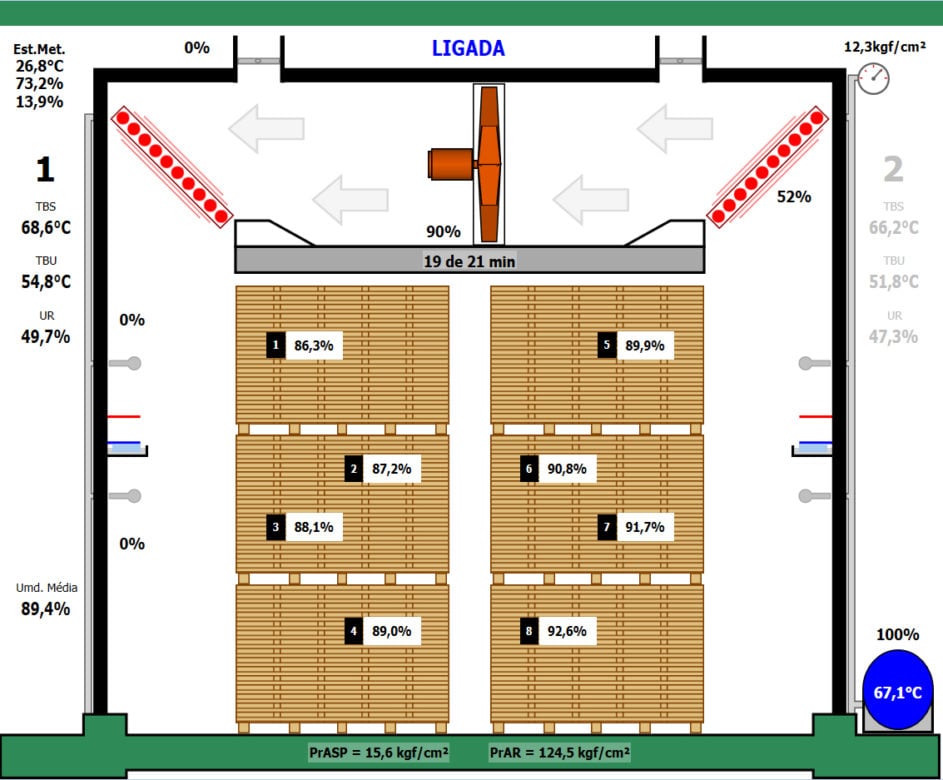

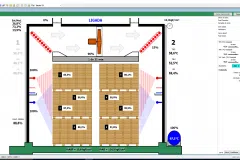

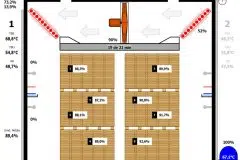

In addition, New Easy controls the essences parameters of the drying process and leads them automatically.

How does new easy guarantee the quality of the final product?

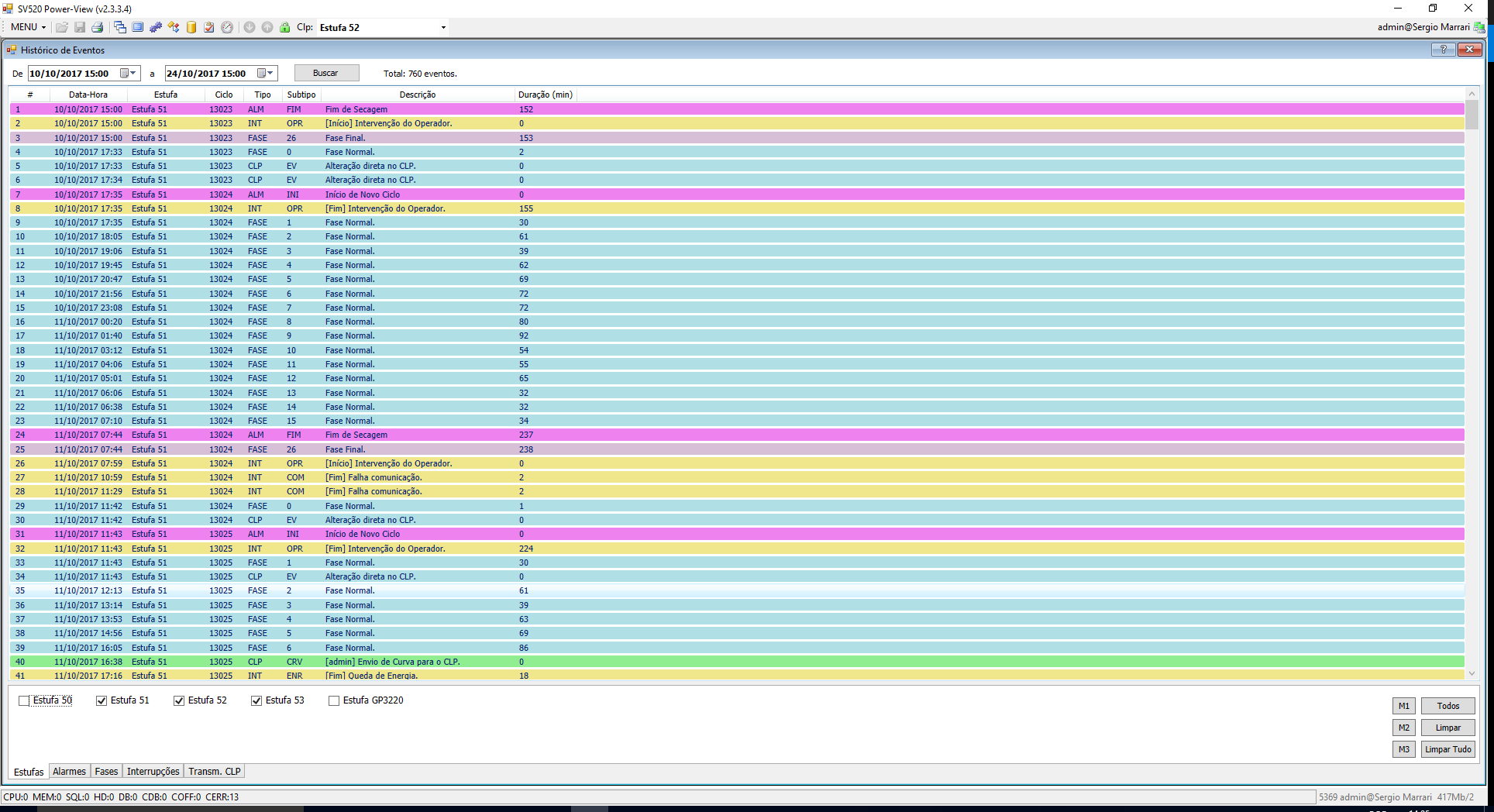

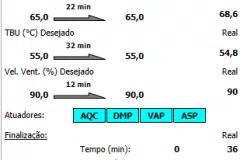

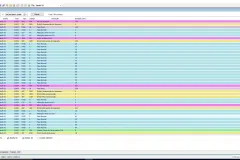

Because it offers the operator several tools in its supervisory, and CLP, so that it obtains a fine control over the drying process. Like curves with decimals of temperature, baths, extra phases and more!

So ensure that your wood at the end of the whole process is without any commitment or cracks in it, that is, without any waste of material or wear of equipment.

Benefits of using an automatic wood drying controller:

- Energy savings: It is capable of automatically adjusting the drying conditions in the kiln, including temperature and humidity, to reduce the energy consumption required for wood drying. This can result in significant long-term cost savings.

- Improved wood quality: With precise control of temperature and humidity, the New Easy can ensure uniform and high-quality wood drying, resulting in less material loss and waste. Additionally, uniform drying can also reduce the likelihood of defects such as warping or cracking, improving wood quality and increasing customer satisfaction.

- Reduction in drying time: With the ability to automatically adjust the kiln drying conditions, it can maximize energy efficiency and reduce the time needed to dry the wood. This can help improve productivity and reduce operational costs.

- Remote monitoring: It allows for remote real-time monitoring of the drying status, which can quickly identify any problems or anomalies in the drying process. This can help reduce downtime and improve operational efficiency.

- Ease of use: It is easy to use and configure, with an intuitive and simple user interface or even direct use from the PLC system. This means that kiln operators can focus on other important tasks while the system efficiently and reliably takes care of wood drying.

And why use the Marrari equipment?

Because our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0. Thus creating a more efficient, productive and modern production environment!

If you want to know more about us and our meters, controlers and mannagers, visit our Facebook or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!