What is the Umiline T Continuous Transverse Moisture Meter?

The UmiLine Transverse, a continuous moisture meter, is the only solution on the market that offers high performance in measuring the moisture content of lumber boards with longitudinal movement. It meets applications with high-speed movement, providing all the necessary features for effective process management.

Why is Umiline T unique in the market?

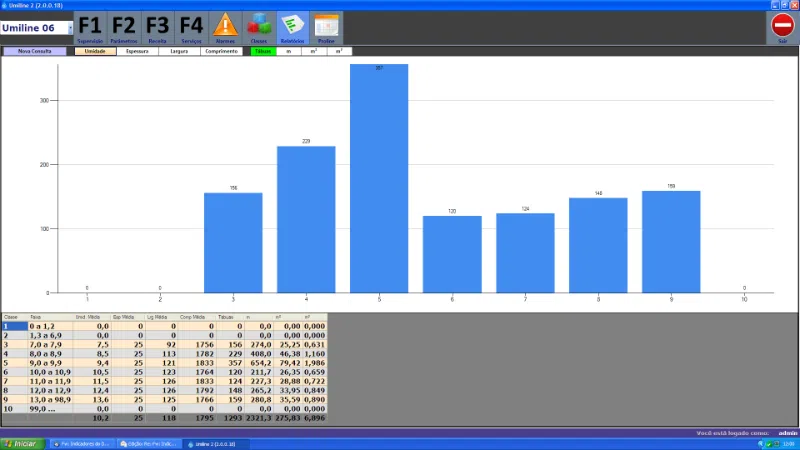

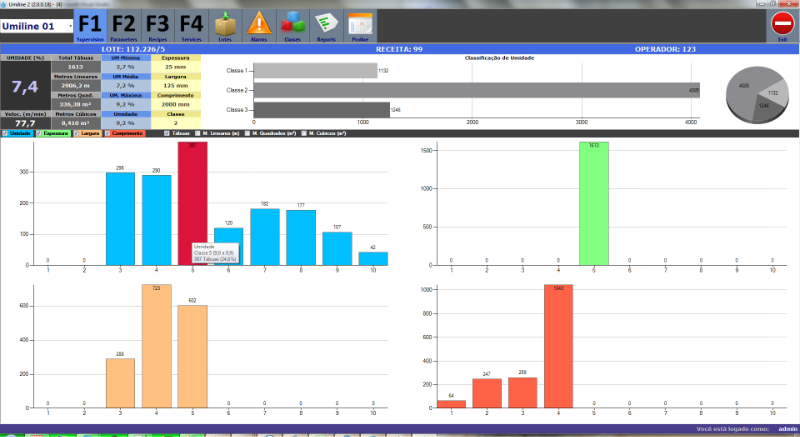

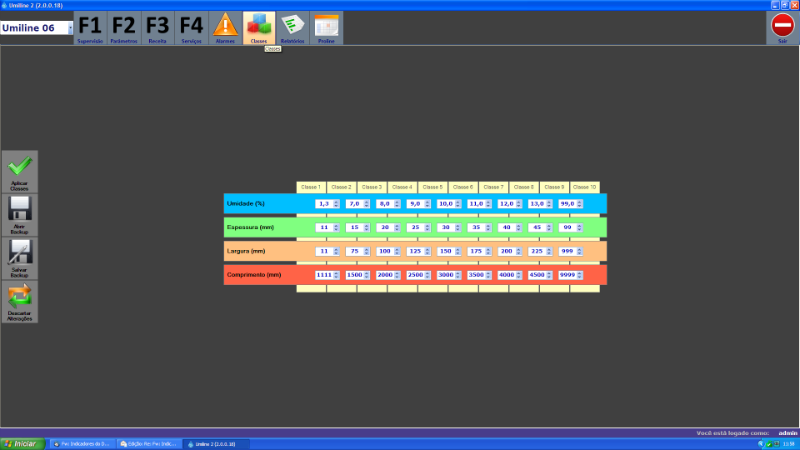

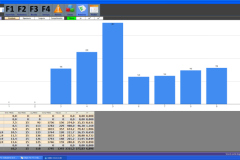

Because it’s Marrari, it offers much more than moisture content verification: it provides automatic compensation for board width, embedded production control with statistical information about the process, OEE reports, and all the features needed to ensure the quality of the final product.

Advantages of an inline moisture meter for wooden boards:

The UmiLine by Marrari offers significant advantages for measuring moisture in wooden boards before processing, such as:

- Quality and efficiency: Measures moisture in real-time with high precision and allows evaluation by average or maximum value, ensuring strict control.

- Smart automation: Features automatic diversion or marking of boards outside moisture limits, optimizing the production process.

- Waste reduction: Prevents the use of unsuitable materials, contributing to better resource utilization.

- Production optimization: Facilitates quick decisions and enhances productivity.

- Final product consistency: Eliminating boards with improper moisture levels reduces quality variations in the finished product.

- Energy savings: Avoids rework or reprocessing of wet boards, lowering operational costs.

- Predictive maintenance: Real-time data can indicate trends of increasing moisture in batches, enabling preventive adjustments.

- Sustainability: Reduces wood and input waste, promoting more efficient use of natural resources.

In summary, a moisture meter on the production line is a valuable tool to ensure quality, efficiency, and compliance in wood drying and processing operations.

How does Umiline T work?

A robust sensor performs high-speed readings, which, combined with intelligent processing, ensures the quality of results and meets high-speed production lines.

WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss, using methods such as OEE and Industry 4.0. This creates a more effective, productive, and modern production environment!

If you want to know more about us and automation news, visit our blog, Facebook, or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!