What is the EcoSteam boiler automation?

EcoSteam is Marrari’s solution for industrial boiler automation, aimed at efficient and constant energy generation. It generates savings through optimization of fuel usage and reduction of gas emissions.

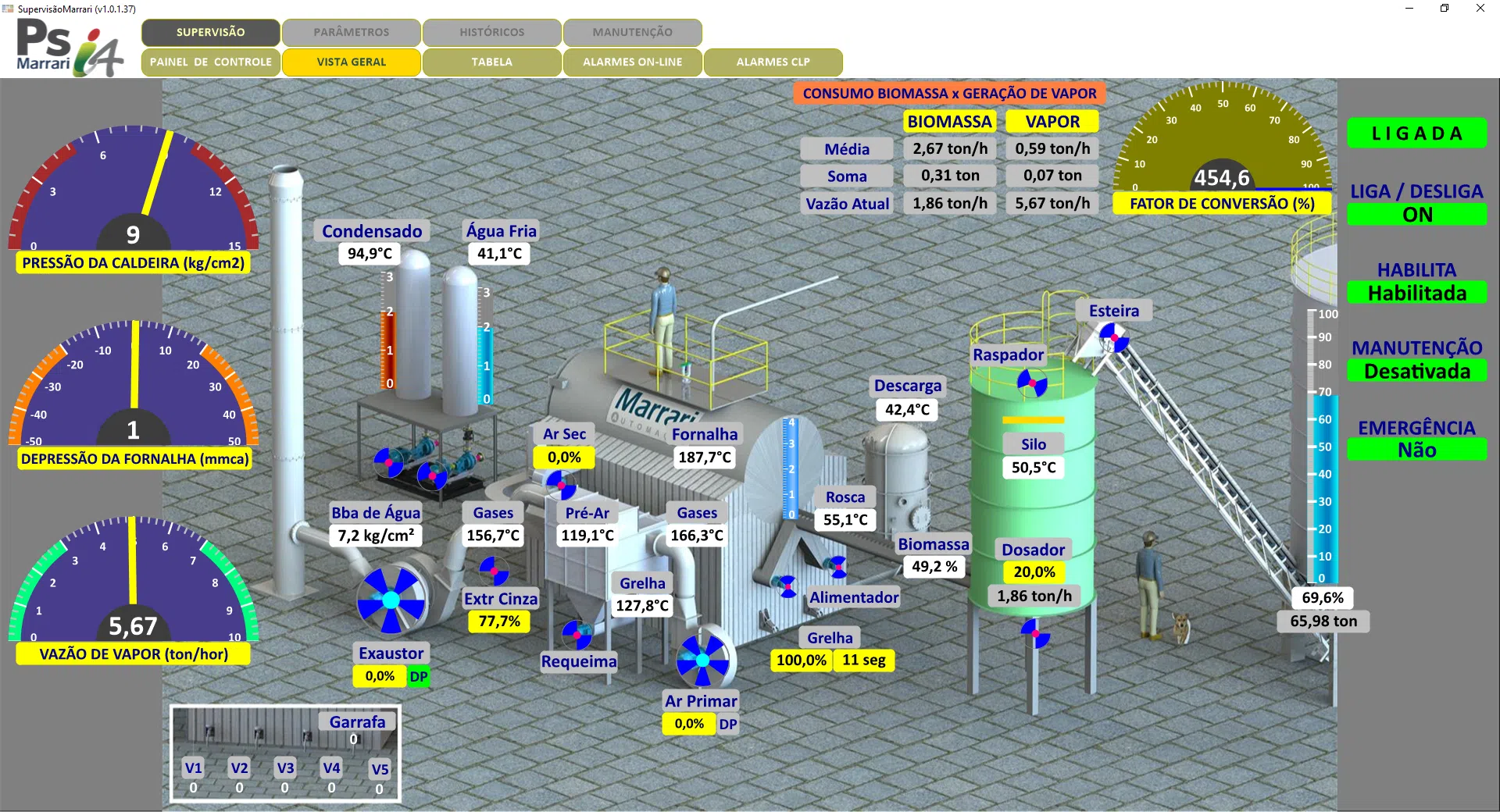

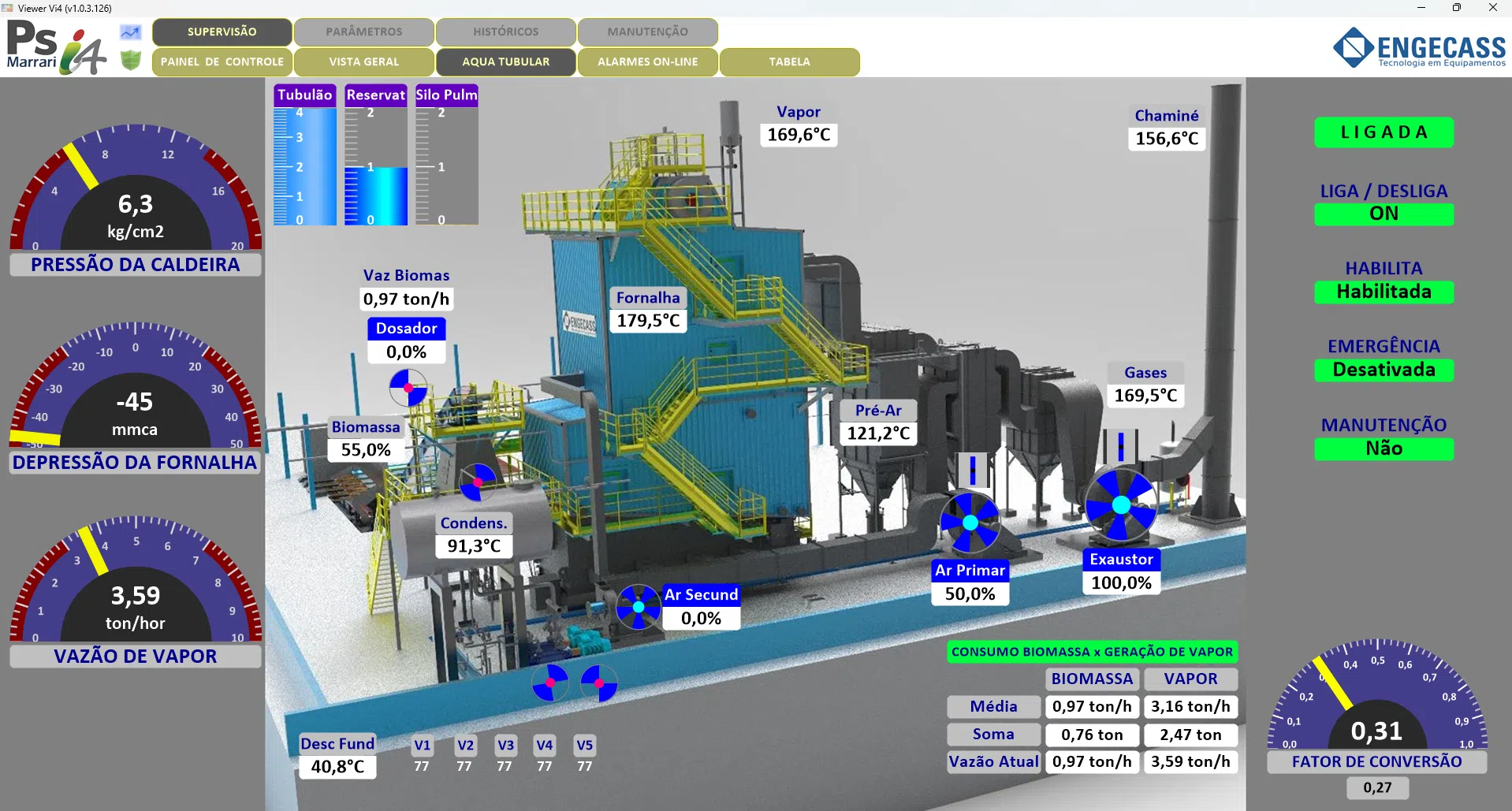

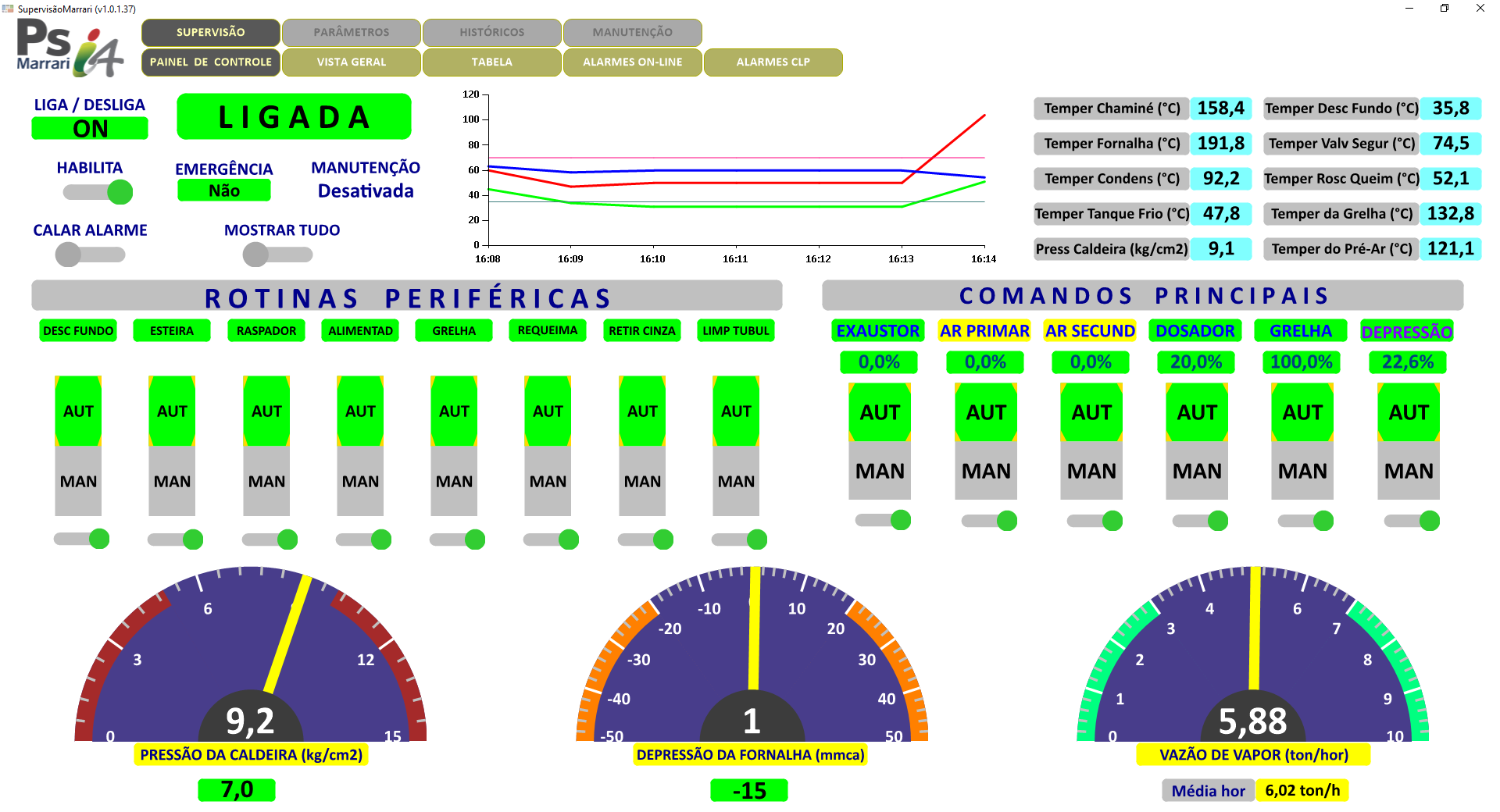

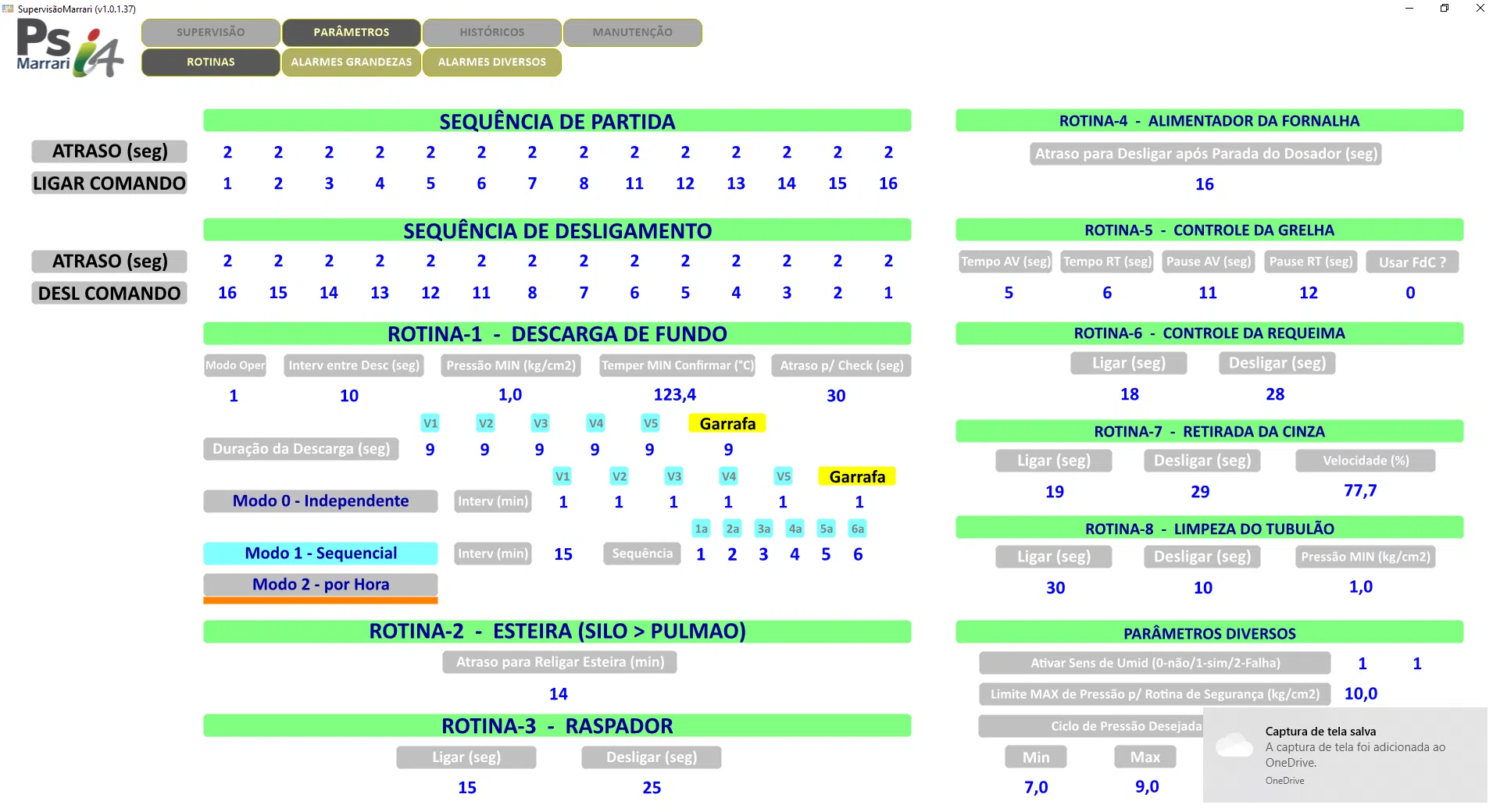

This system allows for complete automation of the industrial boiler, controlling all the main commands as well as peripheral support equipment:

- Level Control

- Biomass Movement Control

- Bottom Discharge

- Cleaning Systems

How does it optimize and improve processes?

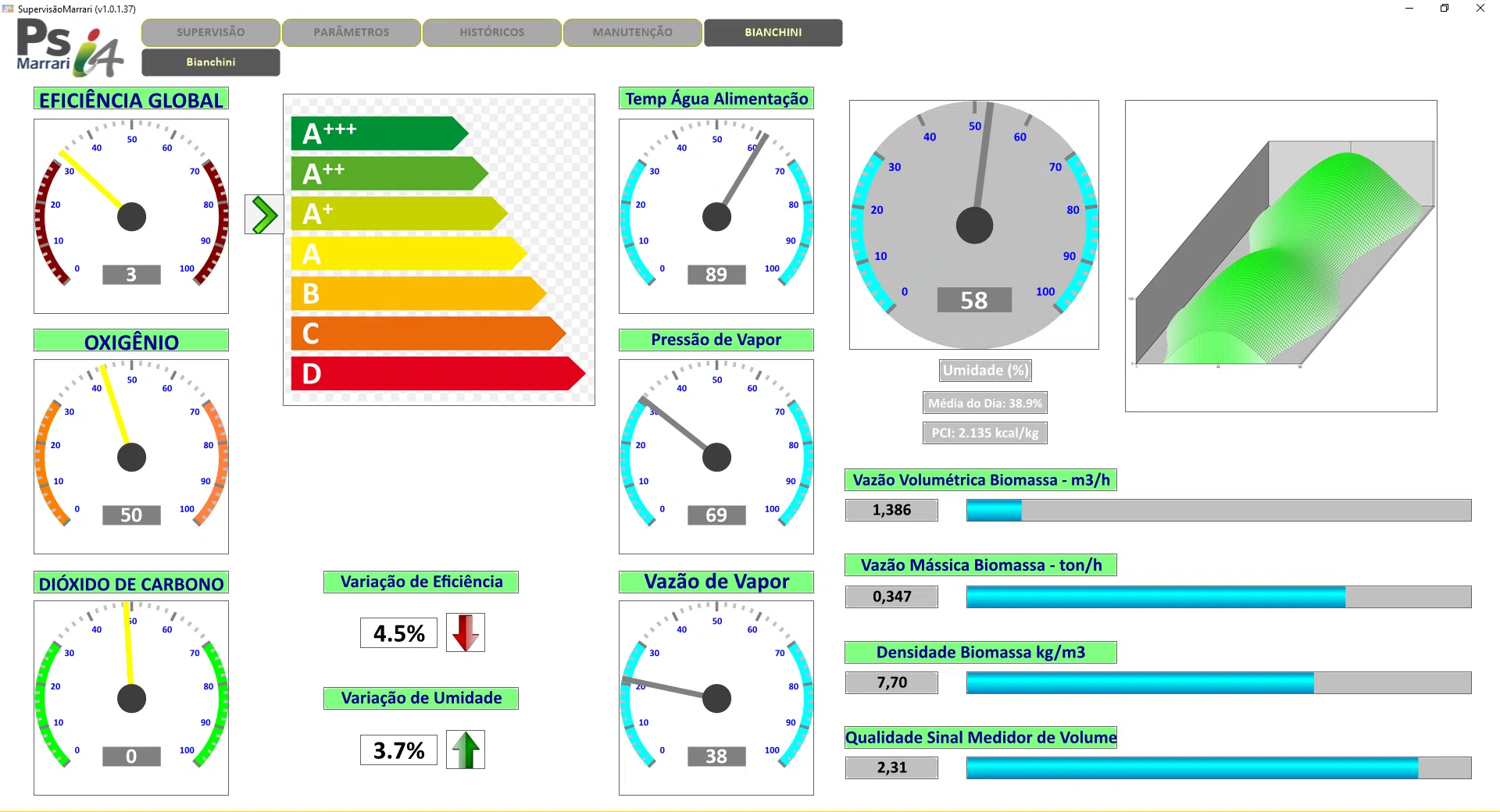

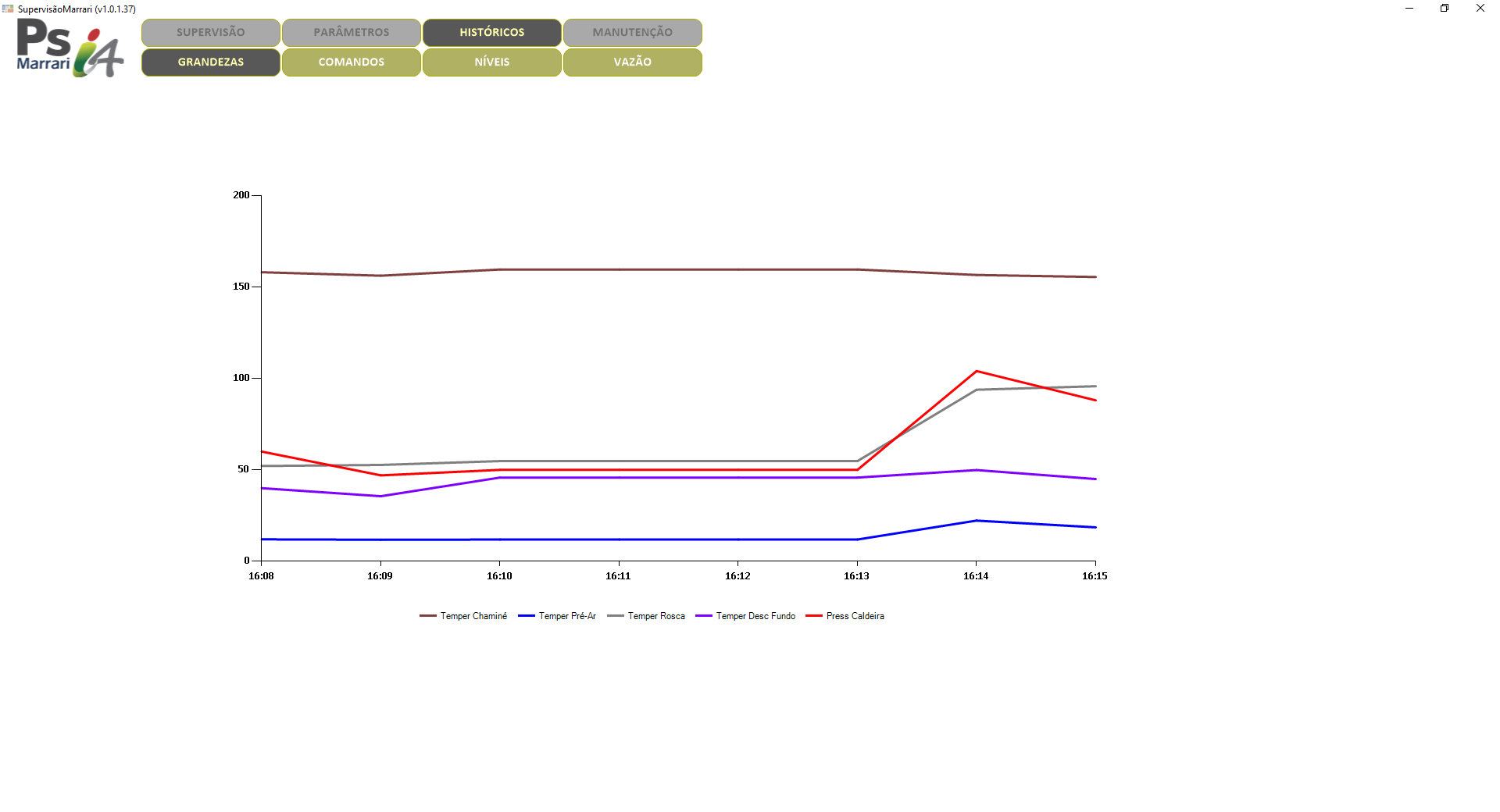

With the boiler automation provided by the EcoSteam control system, the process achieves a high level of efficiency through advanced control and management routines that use multivariable analysis to ensure precise control. The system also includes auxiliary modules for analyzing sensor and actuator historical data based on Machine Learning, allowing for early fault detection and preventing future boiler shutdowns that would result in production stoppages.

Why should I automate my boiler?

Automating an industrial boiler using a system like EcoSteam is an increasingly popular option for companies seeking to improve energy efficiency, reduce operational costs, enhance safety and regulatory compliance, and improve plant availability and reliability.

Automating a boiler means controlling and monitoring the entire steam production process with precision and efficiency using advanced control and instrumentation technologies. This ensures that the boiler operates at its optimal level with optimized fuel consumption and maximum energy efficiency.

In addition, automation allows operators to monitor the boiler’s performance in real-time, quickly identifying any issues and taking corrective measures before they become more serious. This reduces the need for corrective maintenance and increases the boiler’s availability, ensuring consistent and reliable production.

Moreover, the system goes further by keeping you, your boiler, and your team even more connected. It utilizes Telegram to send alerts, failures, and reports to a group consisting of you, your team, and the boiler, so that you are always up to date with everything happening in the operation and don’t miss any percentage of energy efficiency.

What are the benefits of automating an industrial boiler?

- Increased energy efficiency: It is possible to optimize the fuel combustion process, ensuring that the boiler operates at its maximum capacity and consumes only the necessary amount of fuel to meet demand. This can lead to significant energy cost reductions, with observed reductions of up to 10%. The system also provides the conversion factor for the biomass-to-steam ratio, facilitating visualization of the boiler’s energy efficiency and performance.

- Reduced operational costs: Automation can decrease operational costs by minimizing the need for preventive and corrective maintenance. Additionally, automation allows operators to monitor the boiler’s performance in real-time, quickly identifying any issues and taking corrective measures before they become more serious.

- Improved safety: It is possible to accurately monitor and control process variables such as pressure, temperature, and flow. This reduces the risk of operational failures, such as explosions or toxic gas leaks, thereby increasing operator and plant safety.

- Increased reliability and availability: Ensures that the boiler operates within design limits, minimizing the chances of unscheduled shutdowns. This means that production can be consistently and reliably maintained, increasing the boiler’s availability and overall plant efficiency.

How does boiler automation integrate with Marrari equipment?

The EcoSteam system runs on the new PSi4 Platform, which was developed based on the concepts of Industry 4.0. It allows for seamless integration with all equipment installed in the plant and makes this information available to all users, anytime and anywhere, via computer or mobile devices. It can also integrate with existing systems in the plant, reducing implementation costs.

AND WHY USE MARRARI software?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0. Thus creating a more efficient, productive and modern production environment!

If you want to know more about us and news from the automation world, visit our blog, facebook or linkedin.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!