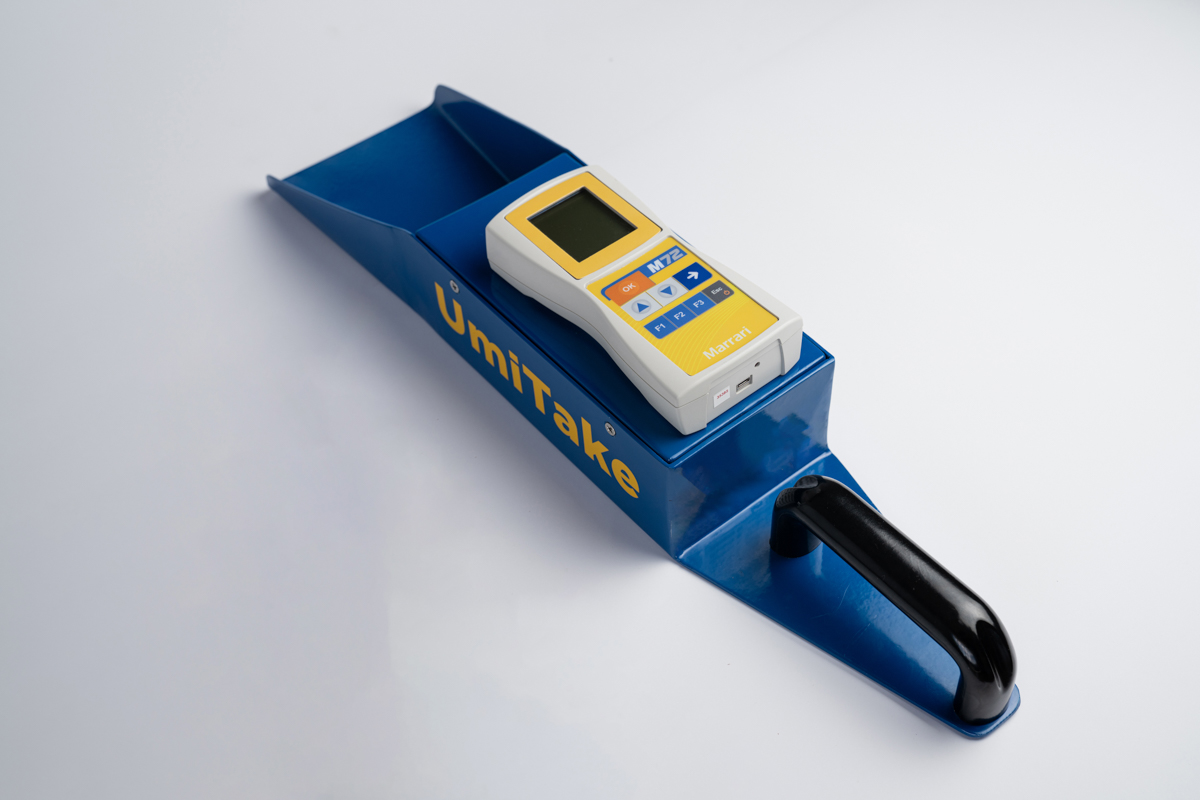

What is the UmiTake M72 Portable Grain and Granule Moisture Meter?

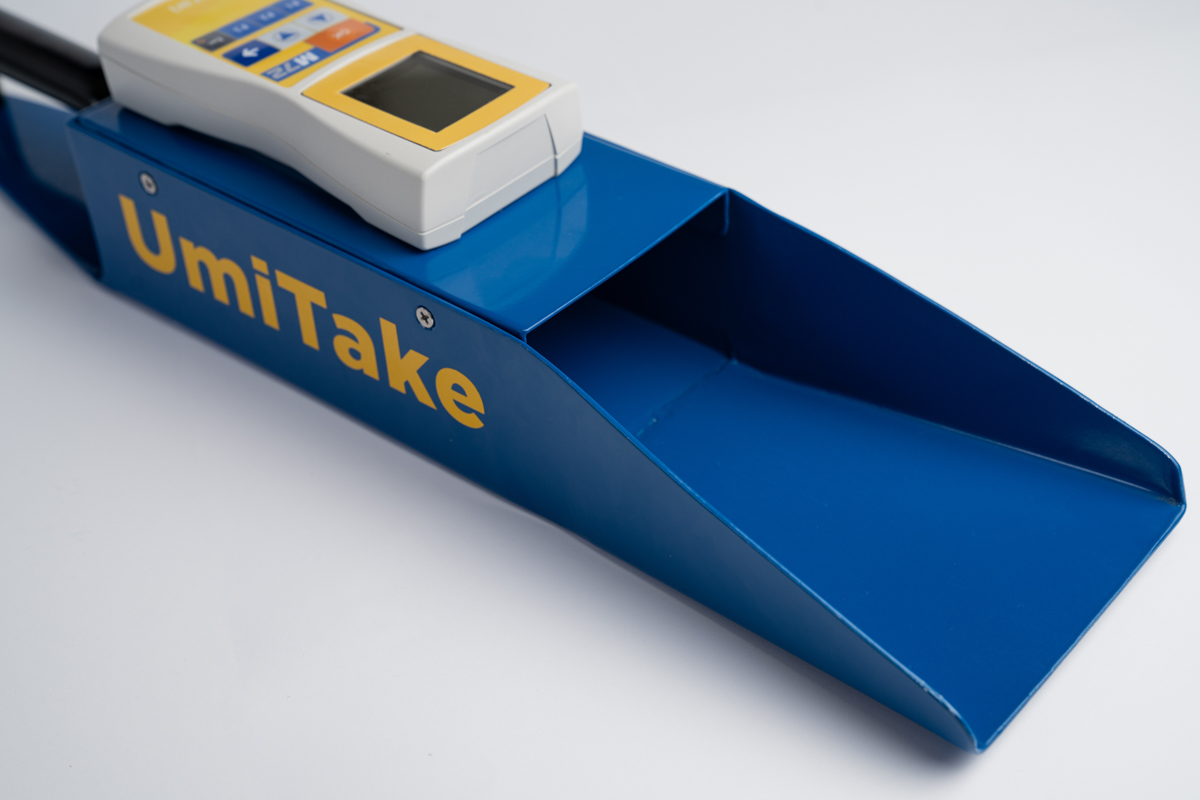

It is a portable moisture meter for grains and granules, designed to evaluate materials of organic origin in powder or granules, with particles smaller than 10 mm (mesh 50). Fully programmable by the user, the equipment allows the creation of specific calibration curves for different types of materials, ensuring measurement accuracy. Its shell-shaped design facilitates direct sample collection during the production process, with results obtained instantly.

With an internal memory capable of storing up to 5,000 records, the M72 UmiTake portable grain and granule moisture meter also records important information such as moisture content, date, time and batch number, allowing detailed monitoring and analysis later statistics.

Advantages and Benefits of a Moisture Meter for Grains and Organic Granulates:

The M72 UmiTake portable moisture meter for grains and granulated materials offers various advantages applicable across different industries. Below are the primary benefits, organized by sector:

1. Agricultural Industry

- Precision in measuring grain and forage moisture: Moisture control is crucial to ensure the quality of stored grains. The M72 UmiTake enables real-time monitoring, ensuring grains are stored in ideal conditions and preventing losses due to deterioration.

- Field convenience: As a portable device, it can be used directly at the harvest site or storage area, increasing agility in moisture control and reducing the risk of quality loss during transport and handling.

- Programmability: Users can create customized calibration curves for different crops, adjusting the meter according to the specific characteristics of each type of grain or material.

2. Food Industry

- Quality control in production: The accuracy of the M72 UmiTake is essential for moisture control in food products such as flours and other granulates. The device ensures that moisture levels remain within the parameters required for food safety and longevity.

- Instant in-line sampling: The ability to collect samples directly from the production line helps identify issues quickly, allowing immediate adjustments in the process and preventing waste of entire batches.

- Storage and traceability: The capacity to store up to 5,000 records and manage 100 distinct groups facilitates the traceability of production conditions, important for quality audits and certifications.

3. Animal Feed Industry

- Moisture control across different ingredients: Ingredients used in feed production have varying moisture levels. The M72 UmiTake facilitates the creation of specific calibration curves for each type of material, ensuring that the final mix has the appropriate moisture content.

- Increased production efficiency: With quick and easy measurements, operators can increase sampling frequency, adjusting the production process as needed to prevent issues with excessive or insufficient moisture.

4. Powdered Food Industry

- Constant monitoring of powdered products: Products such as powdered milk, proteins, and other powders used in food require strict moisture control to avoid clumping and ensure quality and shelf life. The M72 UmiTake is ideally suited for this type of monitoring.

- Reduced losses: With instant readings, the device allows quick interventions in the drying or packaging process, preventing batches with off-standard moisture levels, which can result in losses.

5. Biomass Industry (in powder form)

- Precise monitoring of biomass powders: For powdered biomass, such as sawdust or sanding dust, the M72 UmiTake provides precise and rapid moisture measurement, essential for the efficient use of material in processes like energy generation or pellet production.

- Dynamic process adjustment: Instant readings enable real-time adjustments in the drying or storage process of biomass powders, improving energy efficiency and the quality of the final product.

General Advantages

- Portability and ease of use: Being a portable device, it can be used in diverse industrial environments, both in the field and on the production line, facilitating continuous monitoring and reducing the time required for moisture verification.

- Data storage and statistical analysis: The ability to store records and associated data (moisture, temperature, batch, etc.) enables detailed analysis over time, supporting process optimization and long-term quality control.

- Customization: The capability to create specific calibration curves for different materials allows the meter to be adjusted to meet the very specific needs of each type of product or sector.

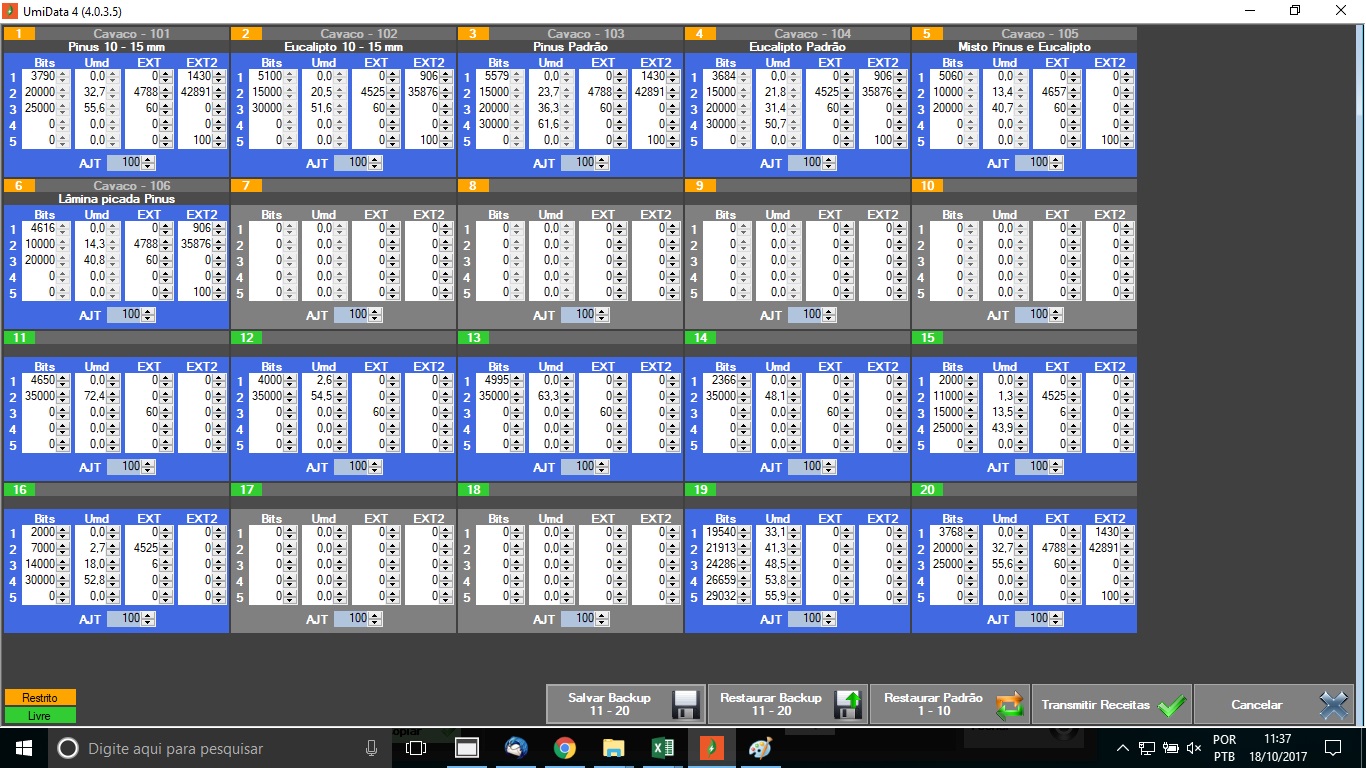

use pre-programmed recipes or create your own recipes

With the UmiData meter and software (below), you can select calibration recipes for specific materials, increasing measurement repeatability and accuracy. The equipment comes with 10 pre-programmed recipes and 10 slots to create your own recipes for your specific material.

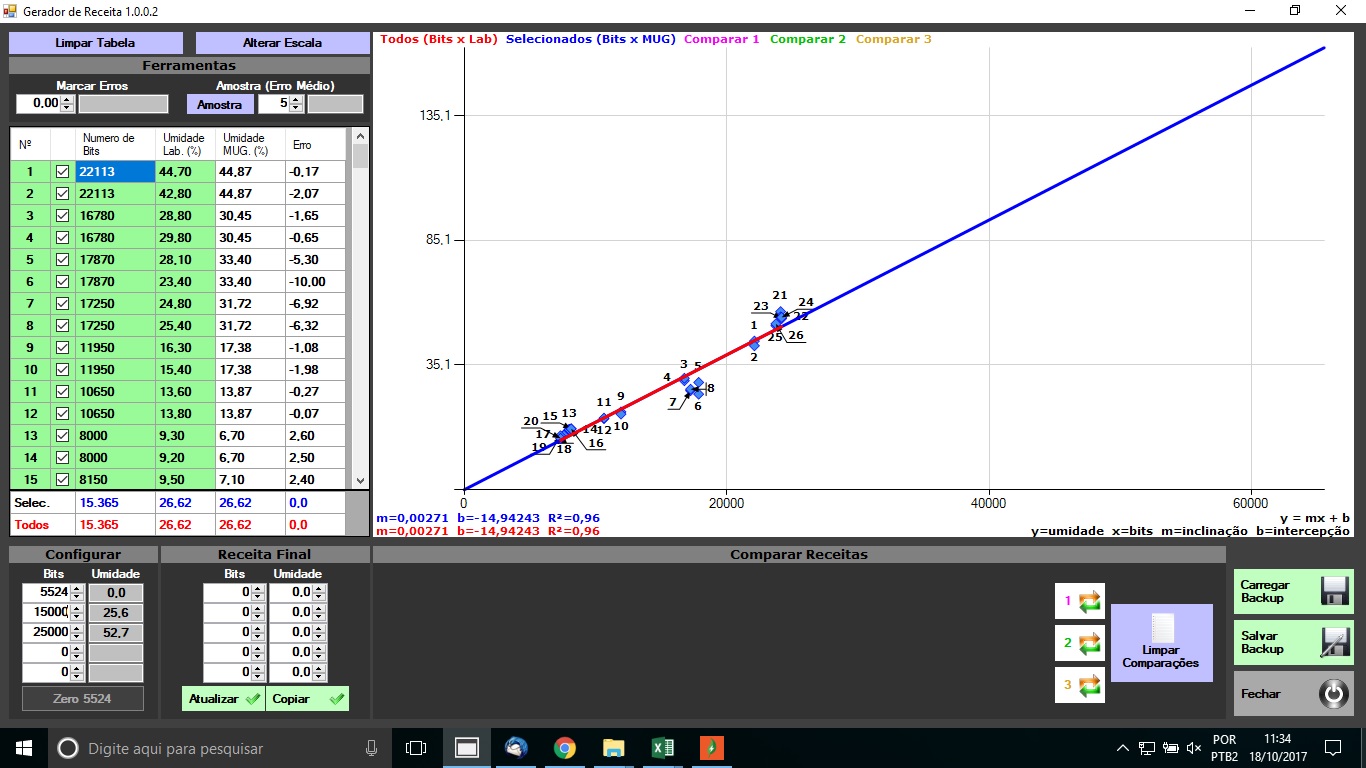

How do you create these recipes and calibration curves?

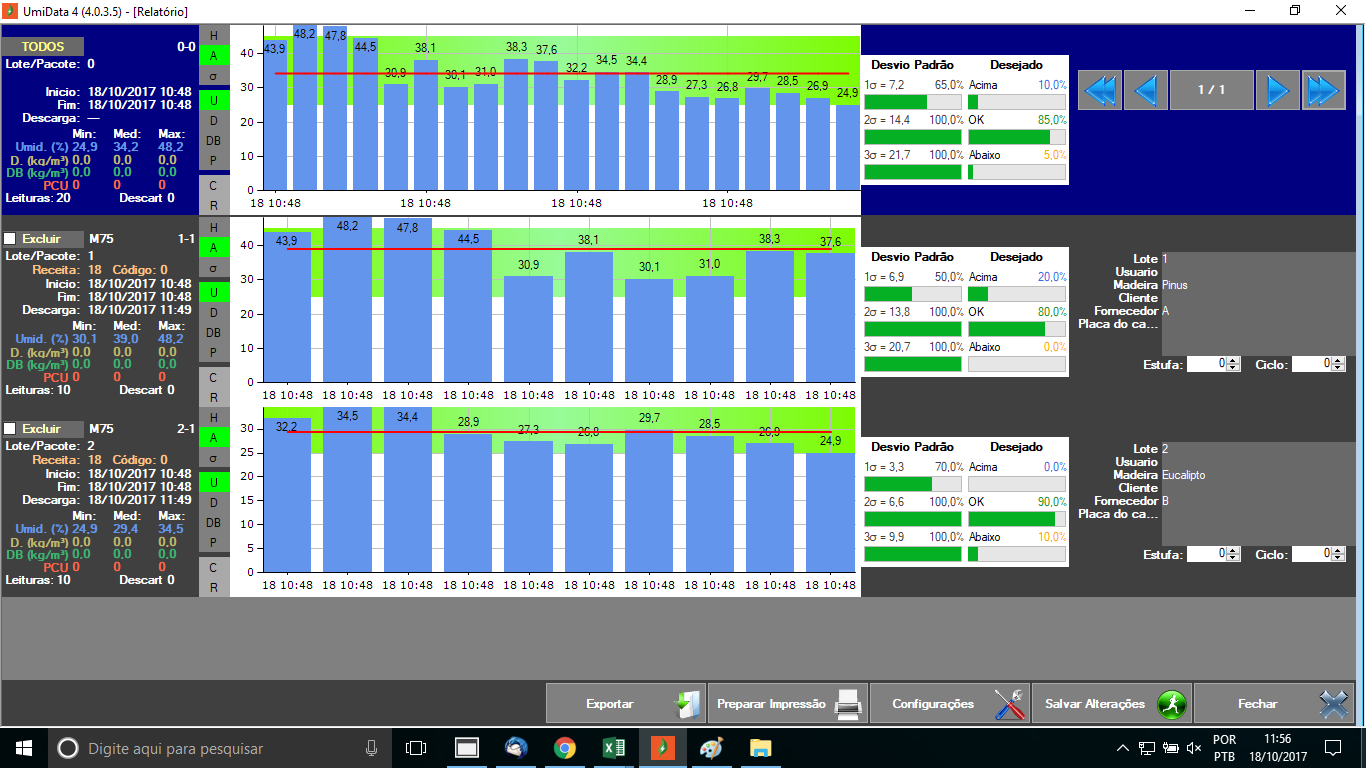

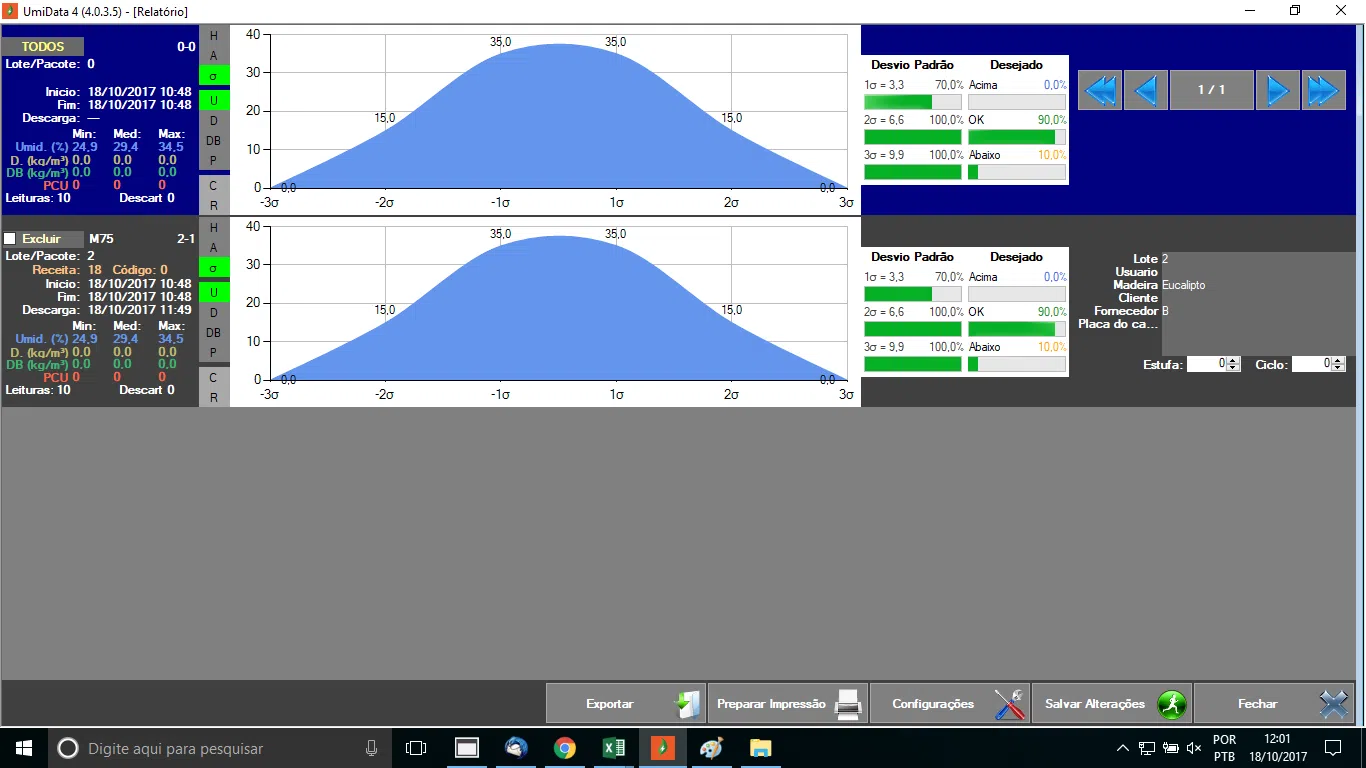

Through our exclusive software, Umidata, a powerful tool for data collection and storage. UmiData analyzes the bits and percentage of moisture present in the samples to then create the specific measurement function (recipe) for a given material.

What is the umidata software?

UmiData is a powerful tool for collecting and storing data. Through this supervisory system, it is possible to create and analyze the recipes present in the equipment.

The collected data (humidity readings) can be downloaded via USB cable to a PC, to be demonstrated through reports, graphs, histories and tables. In addition to viewing these statements online, you can also export them in CSV format to then be read via Excel, thus ensuring better optimization for your company!

If I want to come with the meter with a ready-made recipe for my product?

Yes, just send a sample to our Umilab laboratory, where we will create a unique recipe for your product and also calibrate your equipment.

Get in touch to find out more!

And why use Marrari equipment?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0. Thus creating a more effective, productive and modern production environment!

If you want to know more about us and news from the world of automation, visit our blog, Facebook or Linkedin.

GUARANTEE

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!