What is the Ecopower wood kiln drying manager?

Ecopower’s wood kiln drying manager is the most advanced wood drying control system available on the world market. In addition to the control of each dryer, Ecopower manages and optimizes the energy used in the process, greatly reducing the consumption of thermal and electrical energy.

Why is ecopower a world benchmark?

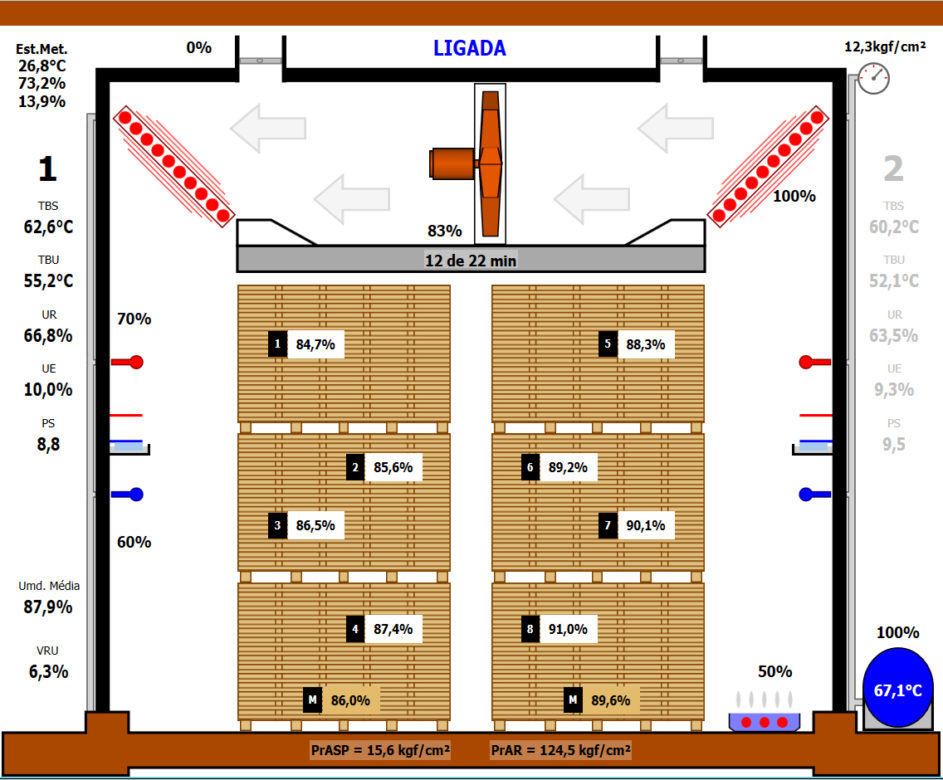

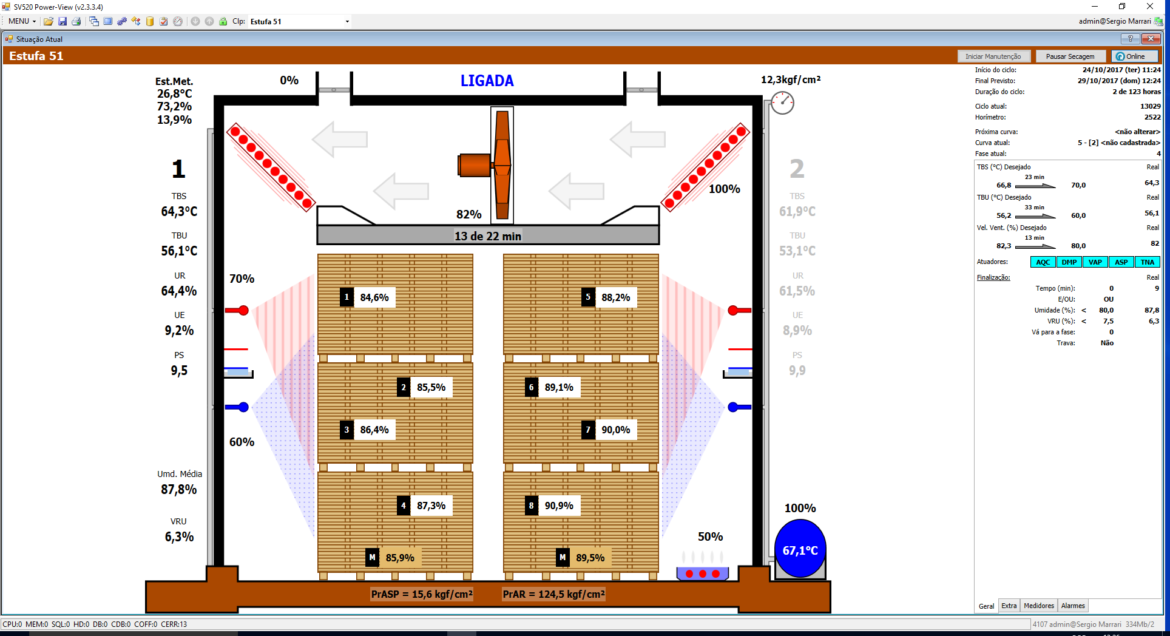

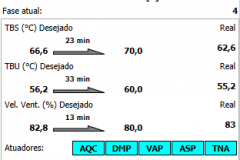

Because it uses the latest technologies in the monitoring requirements of the dryer and boiler, ensures smooth operation of the boiler resulting in steam economy, intelligent control of the starter and reversal of the fans among others numerous resources available in the supervision software.

How does ecopower guarantee the economy of steam and energy?

It ensures savings by reducing the use of steam and electricity. As noted above, it has monitoring routines that ensure smooth operation of the boiler, resulting in a steam economy, spending less on biomass or electricity to keep the boiler running at adequate pressure.

How does ecopower guarantee the quality of the final product?

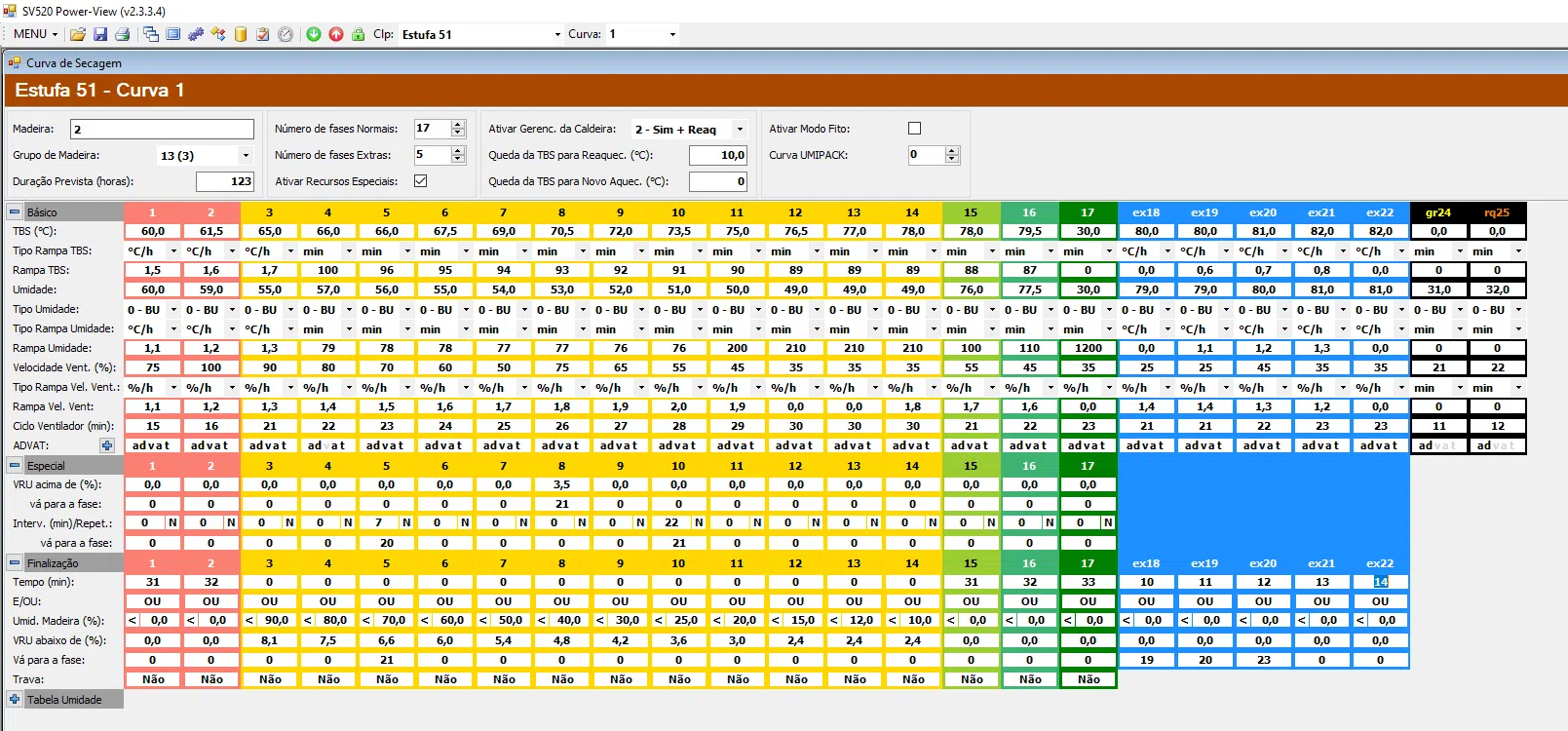

Ecopower has soft drying curves, which makes the wood in its drying process non-thermal shock during phase changes. Securing a always flat wood, without having or bursting.

In addition to the soft-drying curves, it has water and steam bath features that ensure that the final quality of the product is always high.

Benefits of using an automatic wood drying manager:

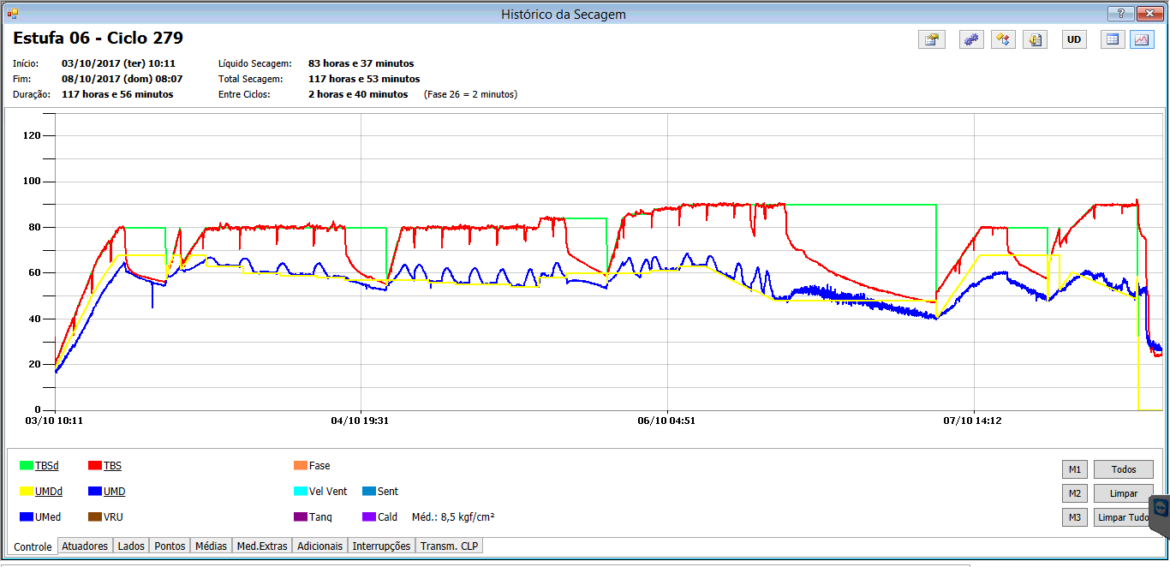

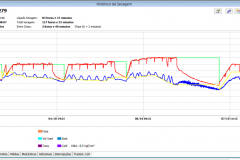

- Efficiency in drying: The drying process is automatically optimized to maximize energy efficiency and reduce the time required to dry the wood. This means that drying is faster and requires less energy, which can reduce operational costs.

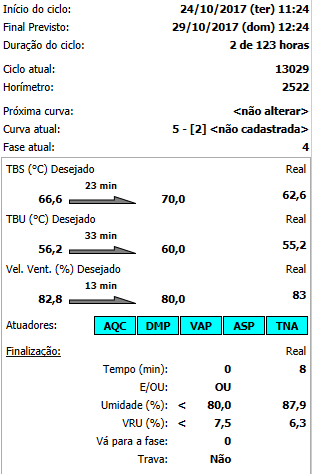

- Precise moisture control: The use of sensors to measure wood moisture in real-time and automatically adjust drying conditions ensures that the wood is dried to the desired moisture level. This helps ensure that the wood is ready for use and minimizes the risk of drying defects such as warping or cracking.

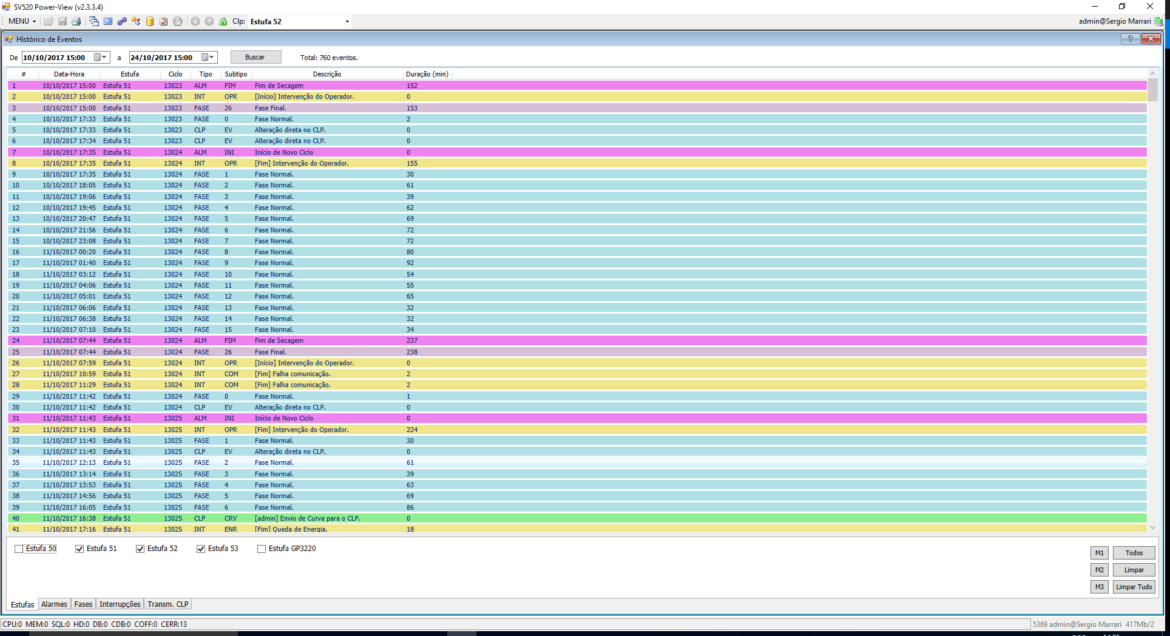

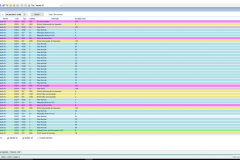

- Remote monitoring: It allows for remote real-time monitoring of the drying status, which can help quickly identify any problems or anomalies in the drying process. This can help reduce downtime and improve operational efficiency.

- Consistent wood quality: It guarantees uniform drying of the wood, regardless of external conditions such as temperature and ambient humidity. This helps ensure high-quality wood that meets production standards, which can improve the company’s reputation and customer satisfaction. Additionally, uniform drying can also reduce the likelihood of defects such as warping or cracking, resulting in less material loss and waste.

- Sustainability: By using sensors to measure wood moisture in real-time and automatically adjusting drying conditions, the amount of energy required to dry the wood is reduced. This can help reduce carbon emissions and make wood drying operations more sustainable.

And why use Marrari equipment?

Because our team is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0. Creating a more efficient, productive and modern production environment!

If you want to know more about us and our meters, controlers and mannagers, visit our Facebook or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!